Condition:New

Type:Logic ICs

Model: LSD-24P30FID2

Scope of application: 12VDC or 24VDC DC motor (operating voltage must be in the range of 12-24V. Motors that are less than 12V or over 24V can not use this product) frequent commutation, the rated working current of the motor does not exceed 6A. The motor should be strictly prohibited from being blocked or short-circuited, or the motor blocking current should not exceed 6A.

If the motor current is large, please use our DC motor positive and negative modules with high current specifications:

https://www.aliexpress.com/item/4000062807085.html

https://www.aliexpress.com/item/4000062753700.html

https://www.aliexpress.com/item/4000062747681.html

https://www.aliexpress.com/item/4000062740068.html

https://www.aliexpress.com/item/4000062628592.html

What are the characteristics of this product?

1. Since there is no contact inside, it can be applied to applications where the motor is frequently commutated. It has no spark and no sound, and has a very long service life. The traditional forward and reverse controllers on the market are all switched by relays, which have a limit on the number of uses and are damaged in a while.

2. Since the control terminal is isolated from the motor, it can be controlled by computer and precision instrumentation. The control signal will not malfunction due to motor interference, and the performance is much higher than that of non-isolated type.

The weakness of this product: Due to the use of power chips, it is known that the overcurrent performance of the power tube is poor, so the motor is not allowed to stall and short circuit, otherwise there will be a chance to damage the power tube inside the product. The customer should install a quick-blow fuse in the motor circuit to protect the product.

What is the difference between this product and similar products on the market?

We will do a brief comparison here to make it easy for you to pick:

1. The main circuit of the same kind of products uses relay reversing, the relays have contact life, and the number of arrivals should be changed. This product has no contacts, so there is no life problem, no sparks or no sound when switching.

2. Similar products are usually switched by ship type switch, which is only suitable for customers with manual control. This product adopts DC signal control, which can realize automatic control by means of PLC, computer, etc., and can also realize manual control by means of external switch.

3. Because of the manual control, similar products do not consider the problem of isolation at all. The control signal loop of this product is electrically isolated from the motor circuit.

4. Similar products can only be used for small motors of several amperes. This product specification is a motor that can be used for operating current (or locked current) not exceeding 6A, but there are also larger specifications for motors with an actual current of 30 to 40 amps.

5. Similar products are bare board structure, no dust and no moisture, can not be used in harsh industrial environments. This product is fully epoxy filled and suitable for a variety of complex industrial applications.

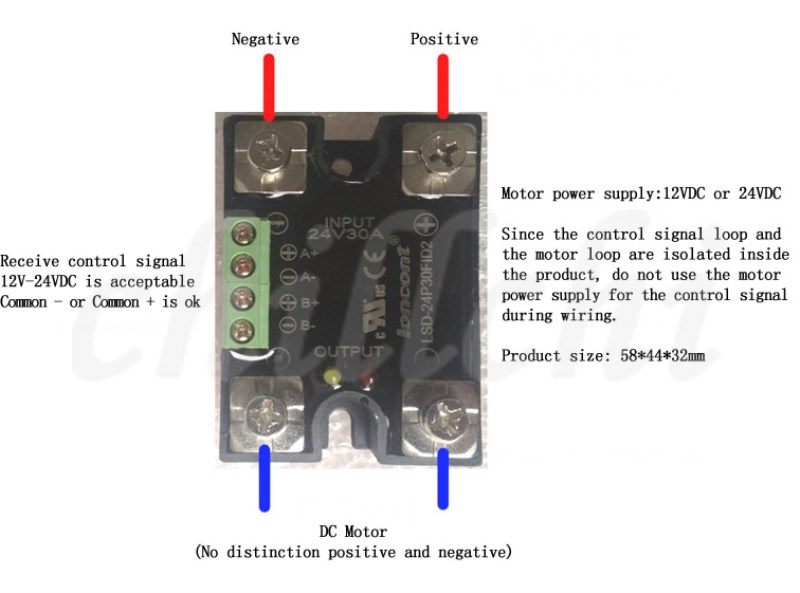

About the wiring of the motor:

Four copper posts are used to connect the DC input to the DC motor. The input DC power should pay attention to the positive and negative poles. The output of the module is connected to the DC motor, and the positive and negative poles are not distinguished.

The input DC power must be in the range of 12-24V, not lower than 12V (for example, 6V, 9V does not work), nor can it be higher than 24V (for example, 36V, 48V does not work).

About the control method:

A+A-, B+B- are signal terminals that control motor commutation. The user can connect A- with B-, control the on and off of A+ and B+, and realize motor commutation. The two negative electrodes are connected by common yin connection. On the contrary, it is a common positive connection. The common yin and the common yang can be selected according to the user's application.

About the control signal:

The input signal range is 12-24VDC. The signal should be a continuous signal and cannot be a high or low level or a PWM waveform.

Since the control signal and the DC motor are isolated inside the product, the control signal input during use and the motor power supply should use different power sources, otherwise the isolation characteristics of this product will be lost.

About the model:

The LSD-24P30FID2 is suitable for 12VDC or 24VDC motors, and the actual operating current (or locked rotor current) is around 6A.

Examples of common questions:

Q: What is the difference between this product and the general forward and reverse switching devices?

A: This product is isolated, and the general products are not isolated. Isolation means that the signal at the control end is isolated from the motor and has no electrical connection.

There is no contact inside the product, no spark and no noise. It is suitable for frequent forward and reverse starting operation of DC motor, for example, switching between positive and negative twice in 1 second.

The input control signal of this product has an interlock function, and when the signal is input, the motor will stop rotating.

Q: What are the advantages of using isolation?

A: When the DC motor rotates, it will generate interference signals on the power supply (RF signal, sudden voltage, and can be observed with an oscilloscope). If the control signal is not completely isolated, the interference signal is fed back to the control terminal, which may cause the signal source of the control terminal to be generated. Malfunctions (such as running dead, etc.).

Q: What is the voltage drop on the module?

A: The pressure drop is around 0.1V. Because the pressure drop is small, the module is basically not hot.

Q: What is the working principle of this product?

A: This product is an actuator that switches the motor forward and reverse according to the signal you give it. It executes commands for control signals (signals of 12V-24V). All you have to do is control it with your signal. Add the signal to A+A- when you need the motor to rotate forward. You need to add the signal to B+B- when the motor is reversed. How to apply this signal is determined by the customer, can be manually switched, can be controlled by sensors, PLC can also be controlled, and so on.

If the user uses multiple small DCs to reverse the 24P30FID2 in one machine

Then you can use this, 5-way type. Equivalent to 5 small DC forward and reverse together.

There are two types, the control terminal common -/common +.

The picture below is common +.

POWER INPUT is connected to the total motor power supply;

V+V+ is the same terminal, connected to the positive signal;

The LOAD OUTPUT is divided into five groups of ABCDE, which are respectively connected to the motor.

When C+ is turned on, the C motor rotates forward; when C- turns on, the C motor reverses.

The other four motors are the same.