Condition:New

Type:Logic ICs

3000W High Frequency Induction Heating Machine Melting Gold and Silver Furnace Iron Parts Quenching Anneal

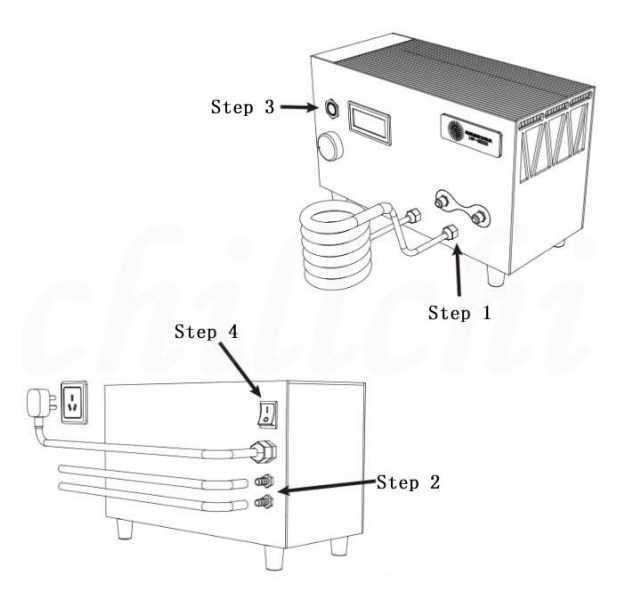

Using method:

Step 1. Install the coil and tighten it with the included wrench.

Step 2. Connect one end of the two silicone tubes to the machine, and insert the other end into the self-provided water tank (10-20L water is recommended, please use a larger capacity water tank for continuous use for a long time)

Step 3. Plug in the power supply, and then turn on the main switch button. At this time, the water cooling/air cooling starts to work, wait 20-30 seconds, when one of the silicone tubes starts to discharge water, you can start heating.

Step 4. After completing the first three steps, press the heating button on the front to start melting/heating the workpiece.

Attention:

Attention: When there is a high temperature crucible inside the coil, please do not disconnect the power or turn off the switch on the back of the machine, let the water cooling system continue to work until the crucible cools. (If it is shut down early, the water inside the water cooling system will boil, causing damage to the pump).

Q&A1. How high can it reach?Answer: In accordance with our standard configuration of 70ML graphite crucible (can hold 1K6 gold), continuous heating for 5 minutes can reach 1190°C, 10 minutes can reach 1500°, and 15 minutes can reach up to 1600°. If we use the special quenching coils that we configure, and the workpieces suitable for quenching, according to the different sizes of the workpieces, the quenching process of about 890°C can be completed in one second to two or three minutes (the time for small workpieces is short, the time for large workpieces is long) .

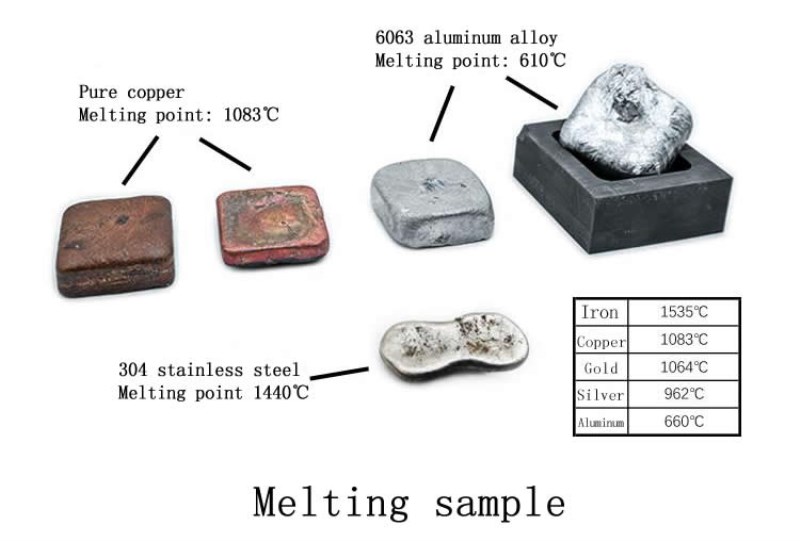

2. Which metals can be melted?Answer: Using our standard configuration 70ML graphite crucible can melt about 1880g gold, about 580g silver, about 500g copper, about 3009 aluminum, about 200g iron at a time (but it is not recommended to melt iron, iron will accelerate the oxidation of graphite crucible), the melting point of the metal Different, different weight, different time, but most can melt within ten minutes.

3. I want to quench my workpiece, what size coil should I buy? Is the bigger the better? After all, large coils can be placed into workpieces of different sizes, and workpieces of different sizes can be used universally!Answer: The induction coil heating workpiece needs to match the good size. Simply put, the large-size workpiece needs a large coil. The small-size workpiece uses a small-size coil. If the large coil is used to heat the small workpiece, the temperature of the workpiece will not rise. Generally speaking, the workpiece The size is preferably about half of the inner diameter of the coil. Workpieces with special shapes, such as flat plates, inner holes, long flat pieces, and other unconventional shapes need to be customized with special-shaped coils. It is best to send samples to our company to test and customize the most suitable coils.

4. Can we weld copper tubes for air conditioning? Can welding tools be welded?Answer: Yes, tell us how big your copper tube/turning tool is, we can provide the appropriate size of the coil.