Condition:New

Type:Logic ICs

Model Number:DL101

Application:0

Operating Temperature:C

Supply Voltage:V

Dissipation Power:W

Color classification:RS485 (default) RS232

Decoration and construction content:Circuit module

DL101Analog to digital conversion module

The hardware version of the DL101 upgrade to V:3.1, software upgrade, the new version supports MODBUS-RTU is hot, support 03, 16 function code, the original agreement to keep compatible, only one instruction, can easily switch between the original ASCII protocol and MODBUS-RTU protocol.

The latest V:3.1 version of DL101 has been added to the optionalRS232The hardware interface, in order to meet the special needs of customers, a small amount of general needs can be directly photographed, large quantity please Wangwang or other ways to contact the buyer, baby number is the real stock, can be directly photographed.

DL101Introduction:

Scope of application:The weighing sensor (for full bridge circuit, half bridge is not supported);

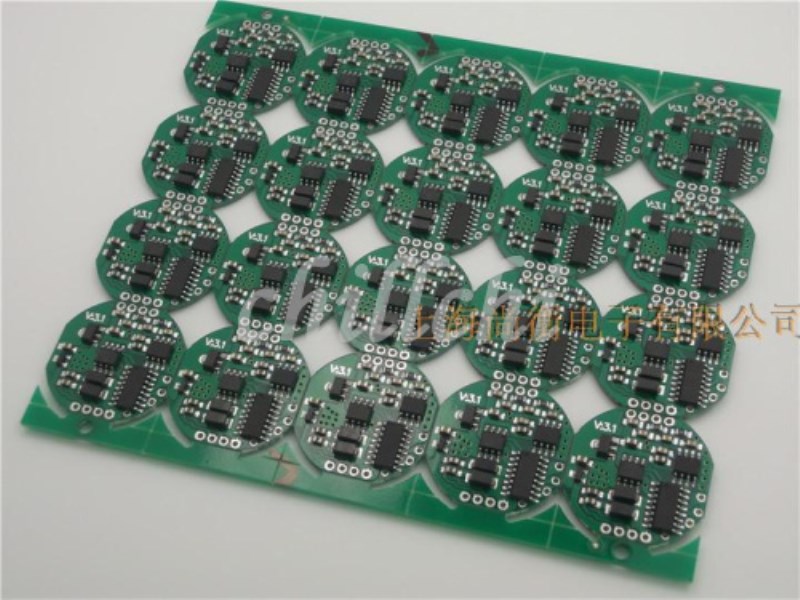

Small size: 28mm * 28mm, diameter 30mm, thickness of less than 4mm;

Ultra thin design: the convenience of ordinary sensors converted to digital sensors;

A/DSelection: 24 bit Delta sigma;

Valid data bit: 18 bit 10SPS;

Temperature drift: <10PPM/

Data rate: 40 - 5 times per second;

Maximum output: + 1040000 yards;

Signal range: + 19mV, differential mode;

Load capacity: 1 impedance not less than 350 ohm weighing sensor

Communication mode: RS485 half duplex (Standard Version); RS232 full duplex (optional version)

Communication speed: 240048009600 (default), 192003840057600bps,

Maximum network number: 63 (can be increased to more than 200 through the modified protocol);

Supply voltage: 6 - DC 12V (recommended voltage: 9V);

Working current: less than 12mA (not including sensor)

Operating temperature range: - 20 ~ 60 C

Application scope: 1) the digital reconstruction of the resistance strain gage type weighing sensor;

2AD data distributed collection;

3Any occasion where a bridge sensor signal is converted to a digital signal.

Instruction set introduction:

1Read digital sensor

2Set module number

3Module zero

4Module full value calibration

5Module return data

- - - - - - - 5 - 1 directives and DL100 compatible with the agreement of all the instructions

6Baud rate setting

7Arbitrary weight loading calibration

8AD sampling rate setting

9AD filter depth settings

10Setting module to send continuously

11,Setting module to send data delay

12Setting index value and zero tracking

13Set the boot to zero and the decimal point.

14Module initialization

15,16Read module in binary mode (compatible with DL100)

17Automatic cycle reading module

18Switch to the MODBUS-RTU instruction set.

19Module zero (equal to zero function of a conventional weighing)

- - - - - - - 19 - 6 instruction for the new instruction set

Analysis of new instructions:

9And the baud rate setting: a new command module will enable arbitrarily set the appropriate rate in support of the baud rate, suitable for different applications;

10And setting module continuous transmission: in one-to-one communication, only the host computer sends a command module, can automatically AD results are automatically sent to the host computer, convenient PC (this command is invalid after shutdown);

11Set the module to send data delay: delay parameter set, can satisfy some slow PC contradiction in speed, ensure the return data will not be lost;

1213, set the index value and zero followed, set the starting point and decimal point: you can make the module with simple instrument function, to achieve the basic function of weighing, not just as a AD conversion module.

14Module initialization: the module all parameters returned to the factory value.

15, 16, binary data read module: DL100 compatible binary command reads the instruction module data, data encoding format has high efficiency, high speed data transmission is very suitable for multi module system, very suitable in the large amount of data transmission occasions.

17, automatic cycle read: PC to send a command to the bus module will automatically turn back the data to PC, PC without the need to send one read command, save computer resource overhead, improve communication efficiency.

18, switch to the MODBUS-RTU instruction set: let the module work in the standard MODBUS-RTU instruction set, and the industrial application of seamless joint.

19, set the zero order: with ordinary weighing instruments, such as exactly the same set of zero function, the addition of this directive, making the DL101 module has all the necessary basic functions of the weighing instrument.

Full chip reflow process