Brand Name:icchipcn.com

Condition:New

Type:Logic ICs

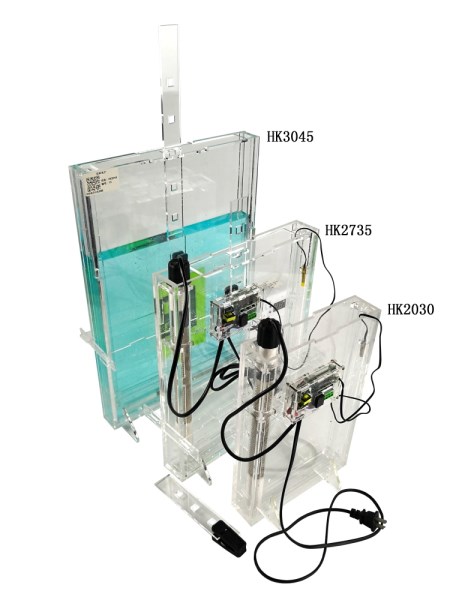

Model Number:HK3045

Supply Voltage:220V

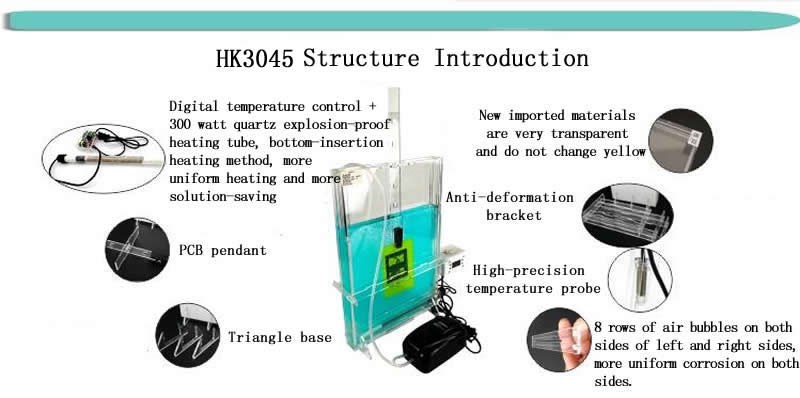

?This etching machine is designed by us for popularization, it is convenient and practical, and the price is cheap. Using high-quality acrylic as raw material, it is transparent and beautiful, strong and durable, allowing you to enjoy the entire exciting corrosion process. All cutting processes are processed by high-power laser cutting machines. It can reach the accuracy of 0.1-0.2MM.

There are a total of four channels and eight rows of bubbles on the double-sided plate. The bubbles are denser and more uniform, and are more suitable for double-sided corrosion. The lead-out part is an acrylic tube, which is very beautiful. , It is convenient for everyone to pour out the solution. The box is inlaid and bonded together by the acrylic plate processed by the card slot. It is very strong. Even if it leaks, it will not affect the strength of the structure. , which can maximize the contact between the corrosive liquid and the board, the corrosion is more uniform, and the base with an enlarged base

plate is more stable.

Product information:Although the name of the product: HK2735Rated voltage: 220VForehead work: 300WBox material: new imported materialsExternal size: 300MM * 450MMCorrosion max size: 270MM *380MMHeating rod: 300W NC quartz explosion-proofTemperature control accuracy: ± 0.1 degreesPreset temperature control: 45 degrees (40-50 degrees recommended)Warning temperature control: Do not exceed 60 degreesBubble point ..: Exclusive cone 4 rows of bubblesAccessories: triangular base, anti-deformation bracket, PCB pendant, oxygen pump

Precautions:

Be sure to follow the instructions and remember not to empty the etching box. Burned out in no time. Installed as shown.

1. Insert the heating rod and add the solution to the top of the temperature measuring probe. How much solution is placed depends on the size of the copper clad laminate. A little one or two centimeters are left for the copper clad laminate to facilitate the splint.

2. We have adjusted the heating rod so that the maximum temperature of 45℃ will not exceed 55℃. .Otherwise the corrosion rate will decrease, and the etching box will be burnt out. You can use it directly, no need to adjust, this temperature is good for the etching machine, and the corrosion speed is not slow.

3. When the heating rod is inserted, dip it in a little water, so that it is easy to insert. Do not forcefully insert it, but rotate it.

4. After etching, please unplug the heating rod.

5. The mixing ratio of the etching box solution is about 200g-300g to 1.5L of water. It is recommended to use 200g to 1.5L. The amount of solution in the box depends on the position of the heating rod. At least it should cover the temperature sensor of the heating rod, otherwise it will keep Heating burns out the etching machine.

The corrosion amount of 200g is about 10pcs of the thickness of 18 copper (half an ounce) of 10*15CM single-panel sub-panel. Please change the new liquid according to the amount of corrosion.

After all, it is a chemical, please wear gloves and put it in a cool and ventilated place when not in use.