Type:Logic ICs

Condition:New

Model:ZK-Motion

Operation mode:Other

Power supply mode:Direct current

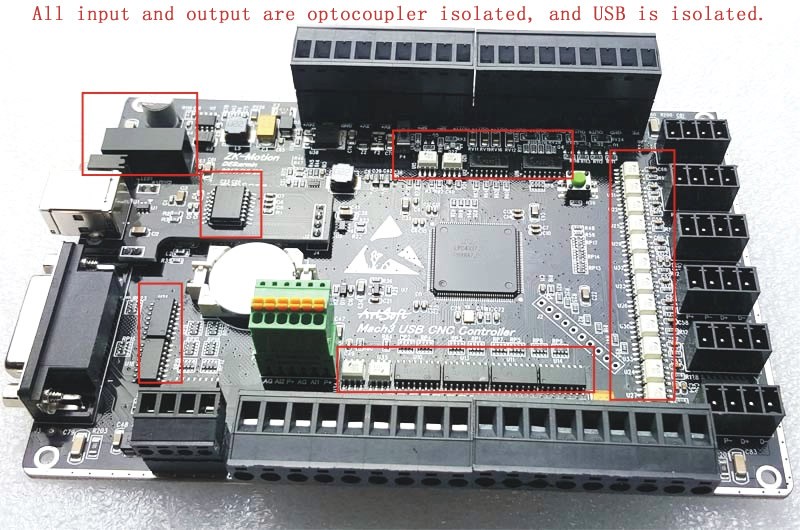

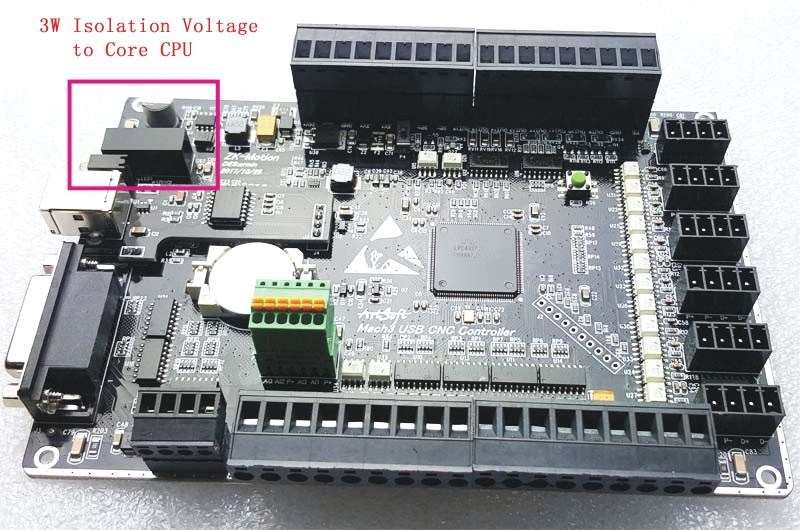

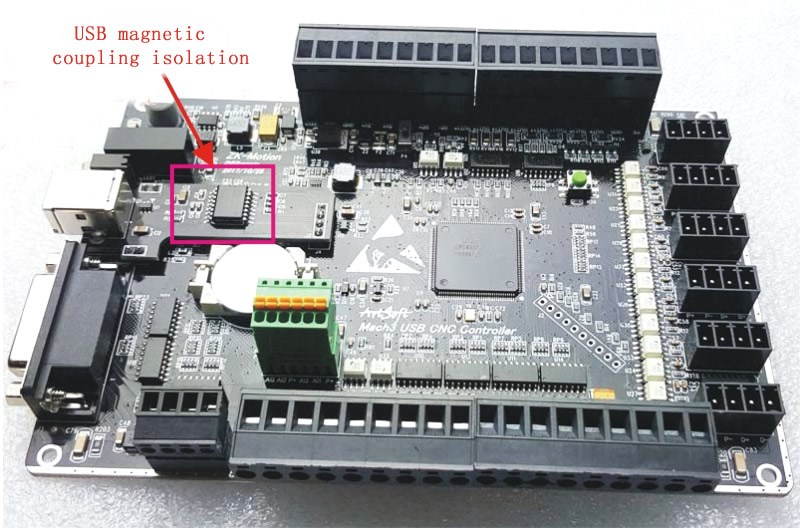

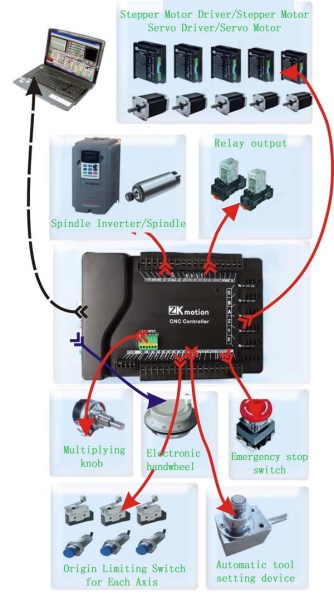

NMotion Upgrade ZK Motion Control Carter Point: Supports all versions of Mach 3, including the latest version. Supporting all Windows versions, including Windows 8 WIN10 USB does not need driver. All Windows versions are plug-and-play and support hot plug. USB bus uses high-end chip magnetocoupler isolation, which is really valuable. It is different from ordinary control card's optocoupler isolation of input and output. It achieves super reliability and absolutely guarantees the safety of computer USB. At the same time, it guarantees the super EMC anti-jamming ability. Single chip, the system is more streamlined, more stable than the general multi-chip processing method. Dual-core ultra-high-speed CPU (single-core maximum main frequency 204MHz) has great redundancy in operation and processing ability. The output frequency of 1000 KHz per axis under 3-axis linkage, 750 KHz per axis under 4-axis linkage and 500 KHz maximum pulse output frequency under 6-axis linkage can be connected to servo/step.

>The size of motion control buffer can be set to ensure that the fastest interpolation cycle can also run steadily, and the computer can run smoothly when the load is too heavy.

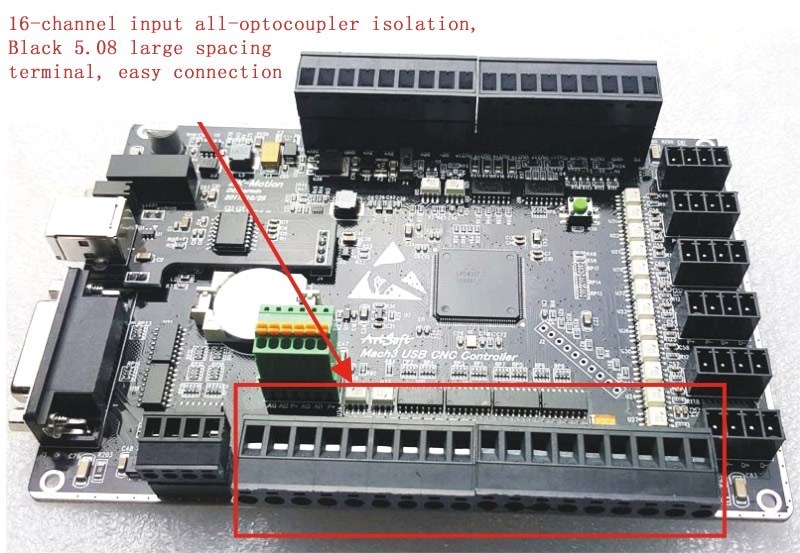

>With 16 isolated input ports, the input interface is simpler, the dry and wet contacts of the ports are all available, and the connection is simpler. The dry contact method only needs to connect a physical switch to the ground line. All 16 input ports have signal indication. The light is on for low level, and the debugging is simple and clear.

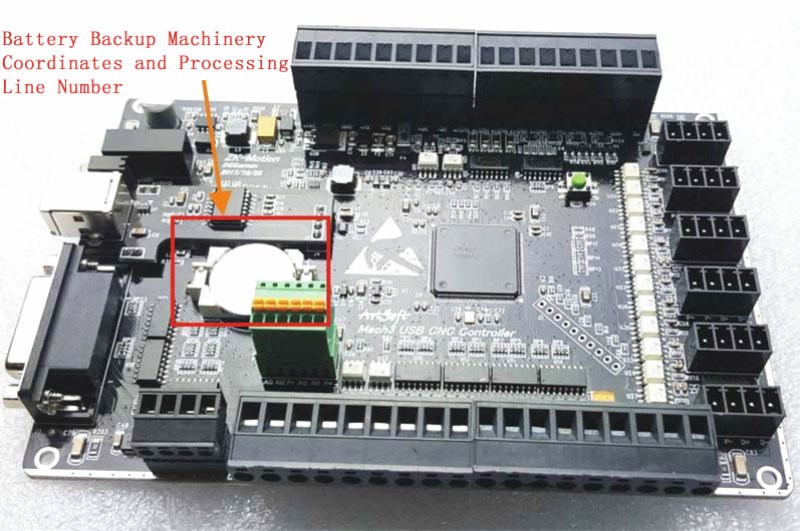

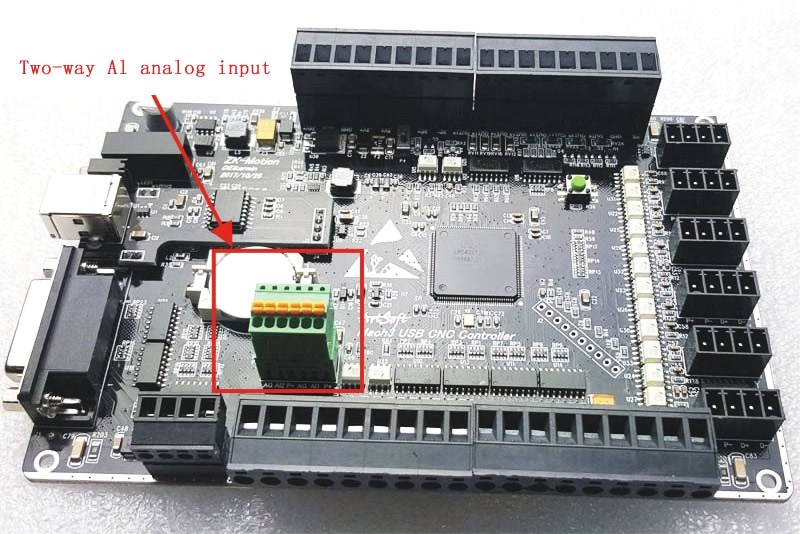

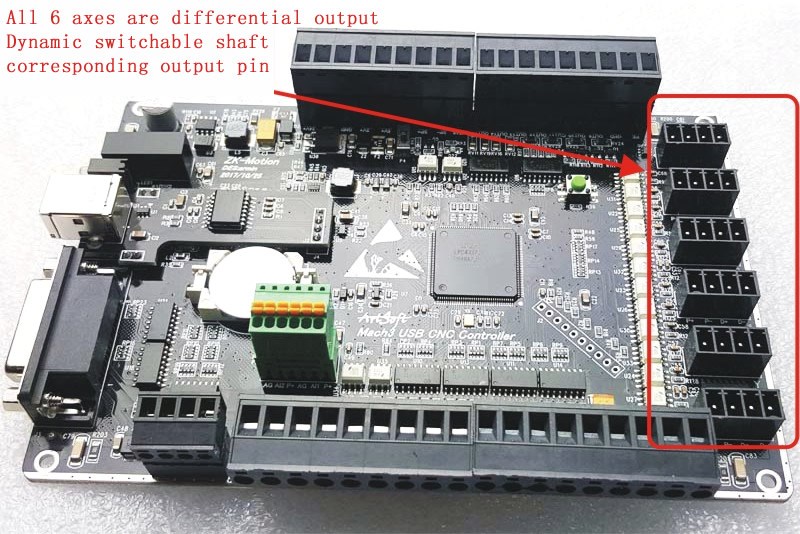

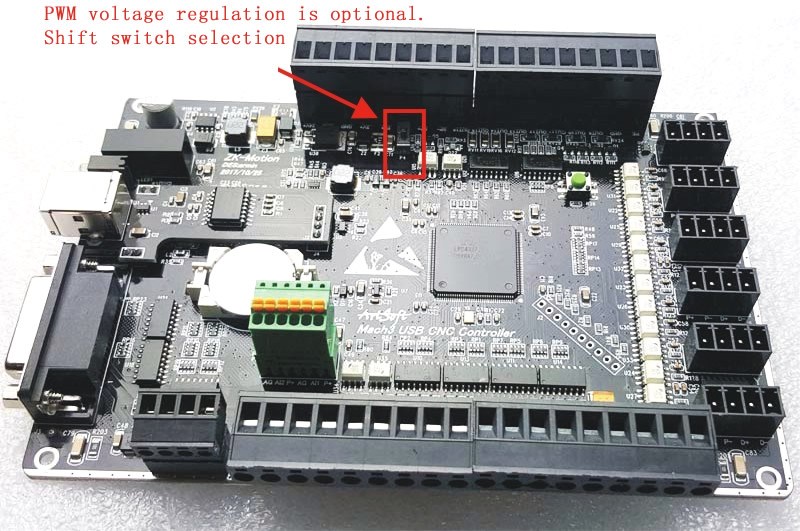

> It has a maximum of 24 output ports (8 self-contained, RS485 expandable), 32 input ports (16 self-contained, RS485 expandable 16). The output port (isolation) of PWM speed regulation can be set up with PWM frequency and duty cycle 0-1000 continuously adjustable. With the function of speed measurement, the actual speed of the spindle can be displayed in Mach3 interface in real time, and the measurement is accurate and stable. The circuit board is carefully built by engineers, and the design level is clear at a glance. With 256 bytes NVRAM space, it can save the coordinate values and processing line numbers of six axes. Next time power on, there is no need to find zero. > All motion axis outputs are differential signals, which can be connected to servo high-speed signal input port.

> The slave axis can be set to support double X, double Y and double Z. Soft Limit Bottom Processing, Safer System

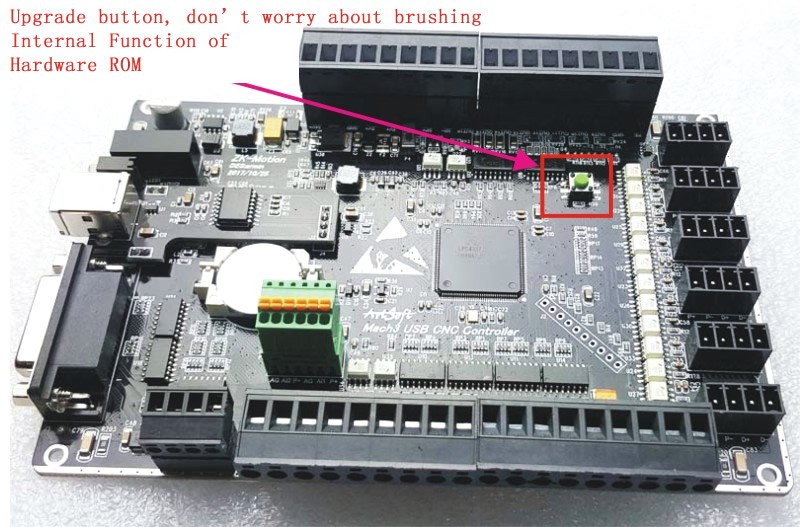

Software upgrade is very convenient, there are emergency brush buttons, firmware brush, USB brush is very convenient, do not worry about brush error, how to brush can be updated by USB.

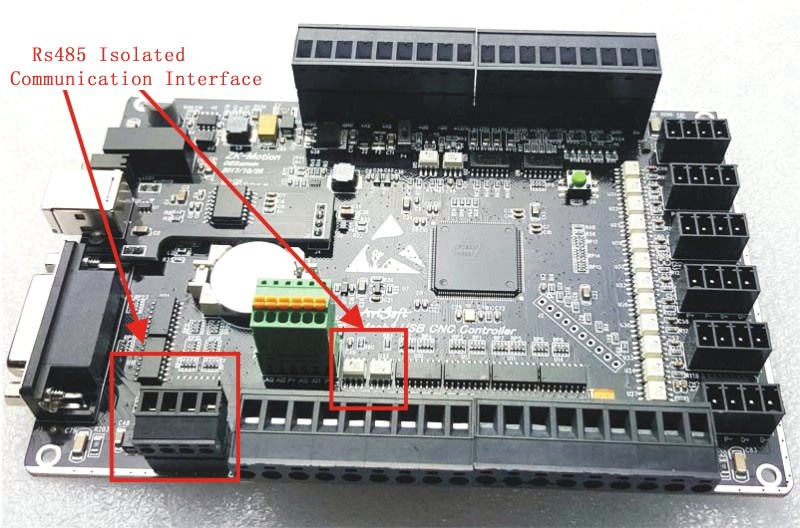

RS485 Isolation Bus, Extended Input/Output or Servo Read Position, Grating Ruler, etc. (Need Customized Development)

Overall isolation, all inputs and outputs are isolated from the motion control core, and high-speed 10M optocoupler isolation is used for pulse isolation. Supporting single and double pulse mode

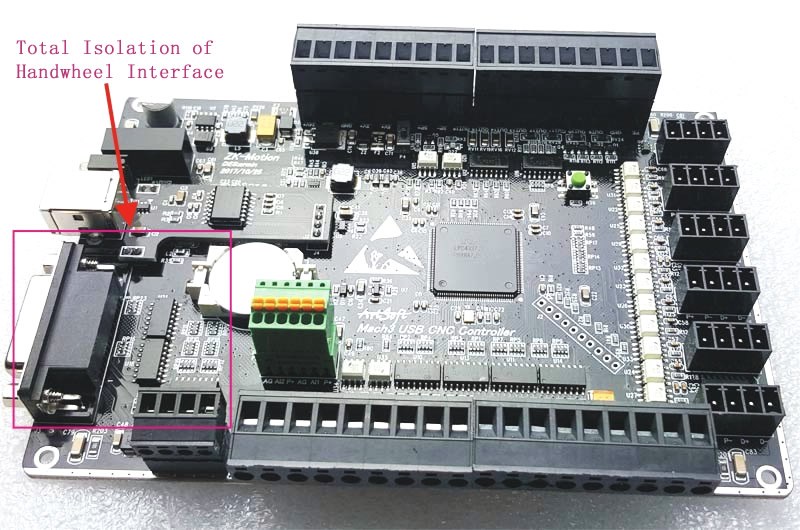

ZKMotion and nMotion upgrades are mainly made up of the following points: 1. Pulse output is high-speed 10M optocoupler isolation, reaching 3-axis 1000KHZ, 4-axis 750KHZ and 6-axis 500KHz speed per axis. 2. Output 8 routes are totally isolated, originally 4 routes, handwheel interface is totally isolated, originally there is no isolation. 3. The input interface only accepts NPN or contact-like dry-node switches, without series resistance and unlimited voltage. It was originally a compatible design of 5VPNP and NPN, and many wiring people would not. 4. With RS485 bus interface, the default expansion of 8-way I/O expansion board can be directly docked, and the docking servo reader can also be developed according to the requirements. Code data. Or connect bus grating ruler.

FAQ:

1. Question: How to install the software? Answer: At present, nMotion's software has made special installation software. There are simple installation files of Chinese culture in Baidu's net disk shared. Just download and install them directly. 2. Question: How to use the control card? Answer: You need to be patient to read the instructions. The instructions introduce the use of pulse ports, input ports and output ports, and the added functions. Please take a moment to see that the control card is generally powered by 24V DC. Specifically, see the manuals of the corresponding products, USB connection computer, and Mach3 installed. The software can be operated after the reset is normal. Generally, it can move when the pulse direction control line is connected. 3. Question: What is the jitter in the processing of control card? Answer: Generally speaking, the software configuration is inappropriate, excluding the computer performance is too low, it is generally caused by the mistake of opening the "constant linear speed cutting" function. Turn off the "constant linear speed cutting" function on the "settings" page. Of course, there are also reasons for the mistake of opening other functions. It is necessary to judge according to the actual situation and go with the curve fitted by points. That's basically why you wobble. 4. Question: The control card will not move after working for one hour? Answer: The activation code is usually transported before the control card is shipped. If the activation code is omitted, contact the shop and send the corresponding activation code corresponding to the SN code. 5. Question: What is the limit of input port, where is the origin and how to connect it? Answer: At present, the control cards have made many wiring diagrams for example, drawing more detailed, the 16 functions of the input port are the same in practice, they are all realized through software configuration, so we need to patiently look at the use of the instruction input port. 6. Question: How to connect the output port and how to use it? Answer: All versions of the output port are transistor NPN output, that is, only pull current effect, without voltage output, so do not quantify the output port voltage. 7. Question: How to connect the spindle converter? Answer: Inverter is used to drive the spindle. The controller adjusts the frequency by sending voltage signal to the converter. There is only one voltage signal and positive and reverse control signal. The wiring is very simple. The specific wiring is not decided by the controller. Look at the manual of the converter. Generally, the manual of the converter is clearer, and some parameters of the converter are more clear. You also need to read the manuals of the converter before you can use them, such as configuring external voltage to control the frequency of the converter, the function of the control port, forward or reverse or other. For example, there are two terminals on the converter, GND and COM, which need to be short-circuited. They are connected to the ground of the power supply of the control card. X2 is reversed. When connected to the O15 of the control card, X1 can be connected to the PWM terminal of the voltage control terminal VI of the O16 converter. Frequency Converter Manual shall prevail.) uuuuuuuuuuu 8. Why can't the handwheel be connected? Answer: 1. Press the TAB key to get out the MPG auxiliary panel, click on the MPG mode/edge-piercing mode/shuttle mode (different versions of the interface call different). 2. Press the white button on the wheels with a sudden stop to hold down the selection ratio of the operation axis. 3) Press the white button on the side to hold the operation wheel, and it will stop as soon as it relaxes. 9. Has the emergency stop button on the handwheel not responded? Answer: The emergency stop button on the handwheel is equivalent to IN17 on the input port, that is, ESTOP port number 2, pin number 17, ZM-Motion version is high level effective, nMotion V5 version is low level effective, you can actually test and adjust the effective level.