Brand Name:icchipcn.com

Condition:New

Type:Logic ICs

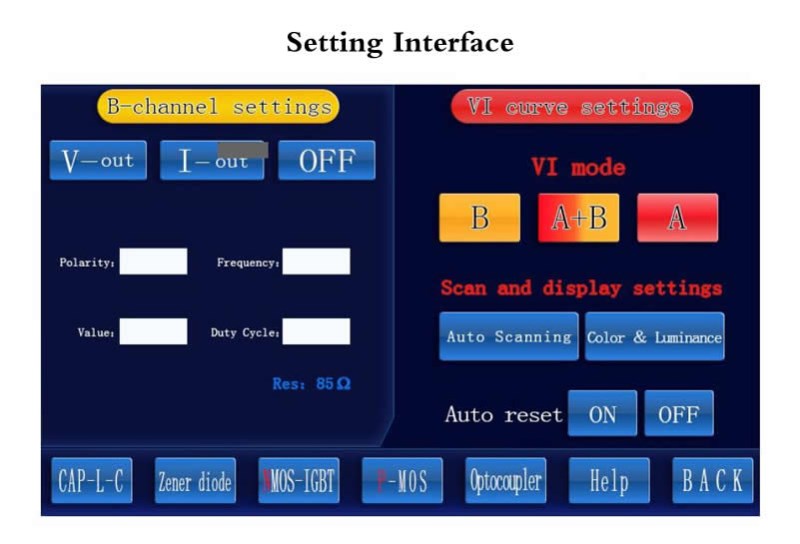

Circuit Board VI Curve Tester

VI curve tester is a unique fault diagnosis technology for components when the circuit is not powered on. can be displayed on the display. Each component has its own specific curve. When the component fails, the curve also changes; therefore, by analyzing the component curve, using the VI curve tester to diagnose the fault technology can quickly and easily detect the component, as long as you compare the curve of a good component with the component under test, you can Immediately draw conclusions.

With the VI curve tester, you can perform the following tests:

①Diagnose unconditionally powered lines

②In the qualitative mode, the special characteristics of the suspected component can be diagnosed

③Using the known component characteristics to compare the characteristics of the unit under test

④Compared with the power-on diagnostic method, the vi curve tester avoids the possibility of short-circuiting other points during power-on testing, which may cause further damage to components or damage to other components on the circuit board.

⑤Safe and reliable diagnosis: don't be afraid of short circuit caused by power-on

⑥?Perform regular repairs by checking whether components are possible and defective.

? Protective Sense Components: ASA's queuing fault technology applies virtually no voltage to the board, which greatly reduces component damage

? Reduce the risk of accidental short circuits

? Qualitative Troubleshooting: For a questionable component, you can identify the substantive problem

⑦ Predict the performance of components to be installed in the circuit

? ? ? ? ? The Tektronix TR210 can visually display the component simulation curve in a curve format when both ends of the component are connected to the instrument. ASA can easily test any passive components: resistors, capacitors, inductors; or solid-state semiconductor components: diodes, transistors, thyristors; and a variety of digital and analog mixed-signal IC chips. When diagnosing a circuit board fault, the composite curve is composed of various component curves between nodes on the circuit. By understanding the meaning of the different curves, you can determine the specific fault location of the component.

Dimensions:

Length: 20cm; Width: 15cm; Thickness: 4.4cm

7 inch color LCD screen; touch screen operation

Host weight: 1.1 kg

VI output characteristics:

1. Frequency: 1Hz~20KHZ, step by 1Hz (continuously adjustable)

2. Normal mode voltage: 0.6v 4v 8v 16v; High voltage mode: ≈80v

3. Output internal resistance: 10 ohms~12750 ohms, step by 50 ohms (continuously adjustable)

4. Output current: 400 mA

Signal generator:

1. Square wave voltage: 0V~16V continuously adjustable

2. Square wave current: 1mA~99mA continuously adjustable

3. Output duty cycle: 1%~99% continuously adjustable (valid in both voltage and current modes)

4. Output frequency: 0~10KHz continuously adjustable (valid in both voltage and current modes)

5. Positive and negative polarity output: voltage 0-16V, current 1-70mA, frequency 0-10000Hz

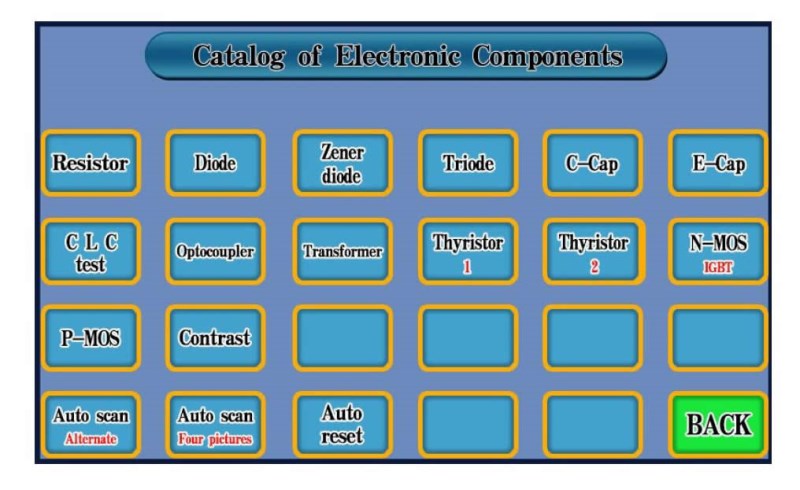

Main functions of VI curve tester:

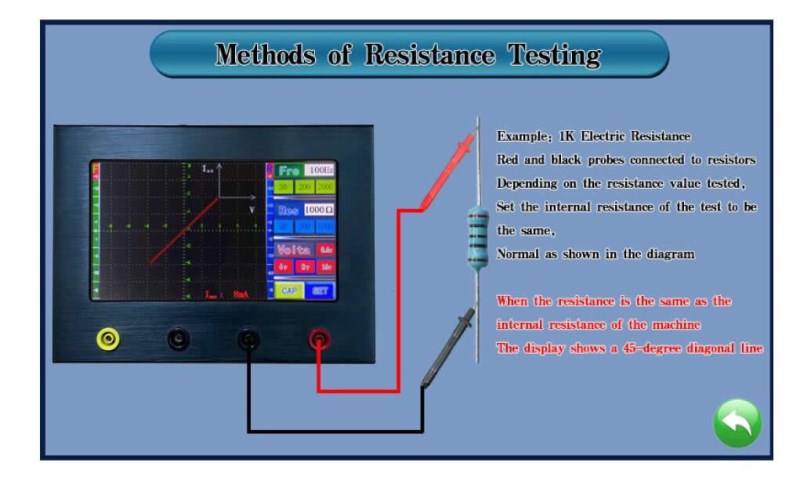

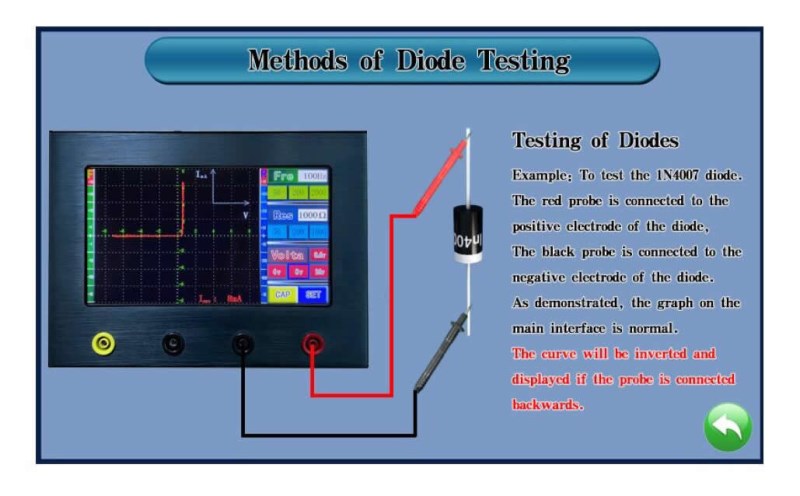

1. It can test a single component offline, test the VI characteristics of any component, and accurately analyze whether the device is damaged or damaged (the degree of accuracy far exceeds that of a multimeter).

2. The quality of various components can be tested online (the VI curve setting needs to be adjusted according to the situation).

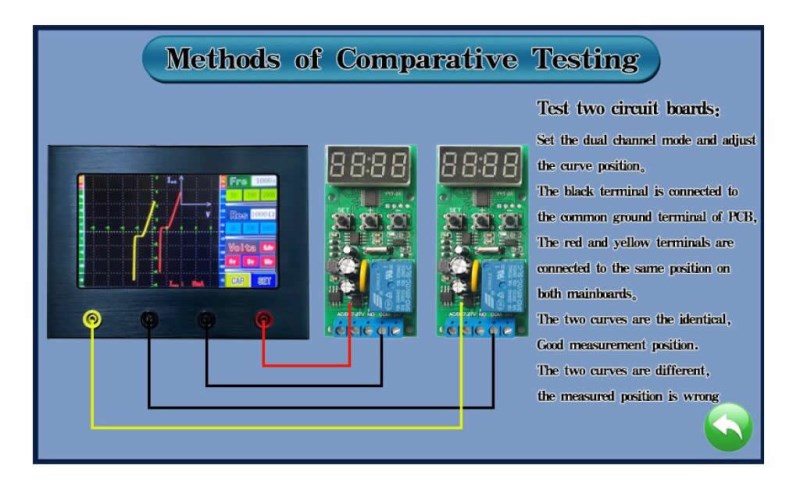

3. It can be used to test the change of VI characteristics of each point on the entire circuit board, judge the characteristic relationship between each device, and quickly find the damaged device (it is more convenient and faster to have the same circuit board or symmetrical circuit).

VI curve tester features:

1. It is convenient and safe to test the quality of components without powering on the circuit board.

2. Use the hyperbolic mode to compare the same or symmetrical circuits, and the screen will display the VI characteristic curves of the two circuits under test at the same time, which can quickly and accurately find the fault point.

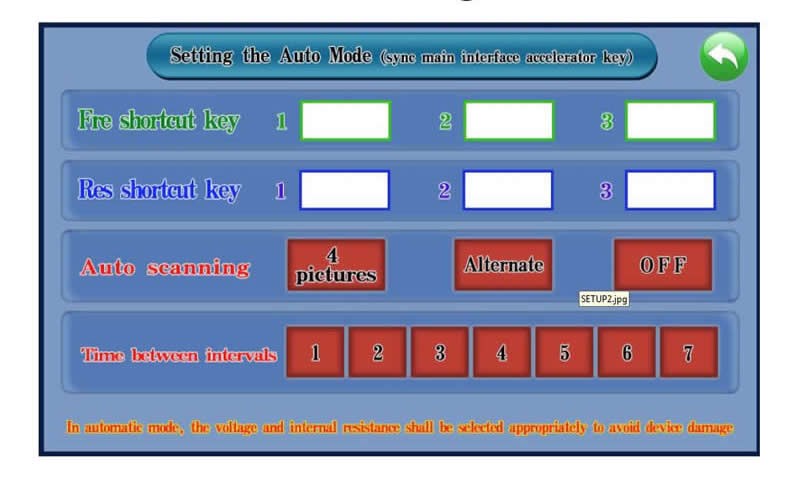

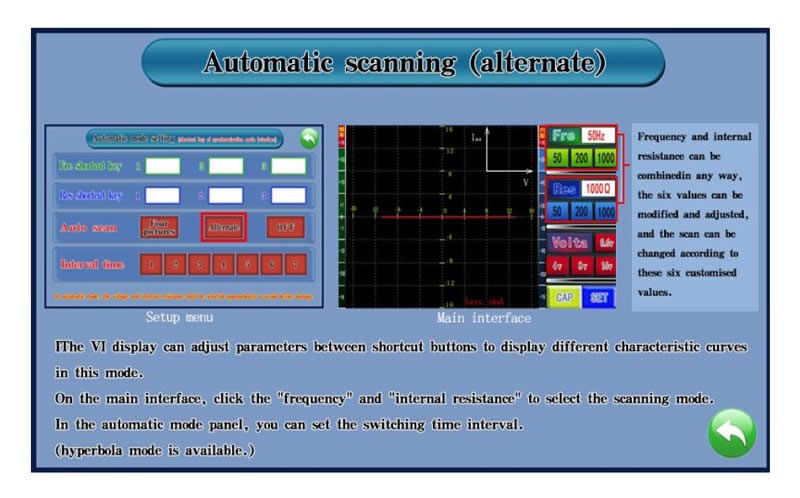

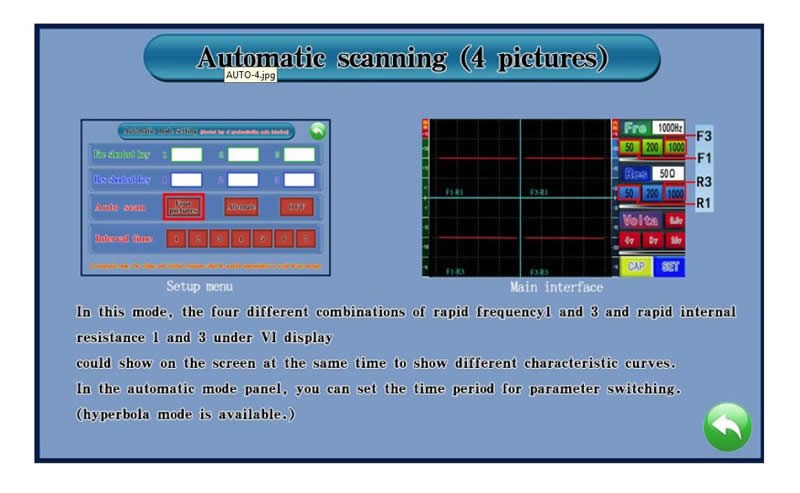

3. The automatic scanning function is added, which can automatically change the frequency and internal resistance, quickly and accurately determine the characteristic curve of the detection point, and improve the detection efficiency.

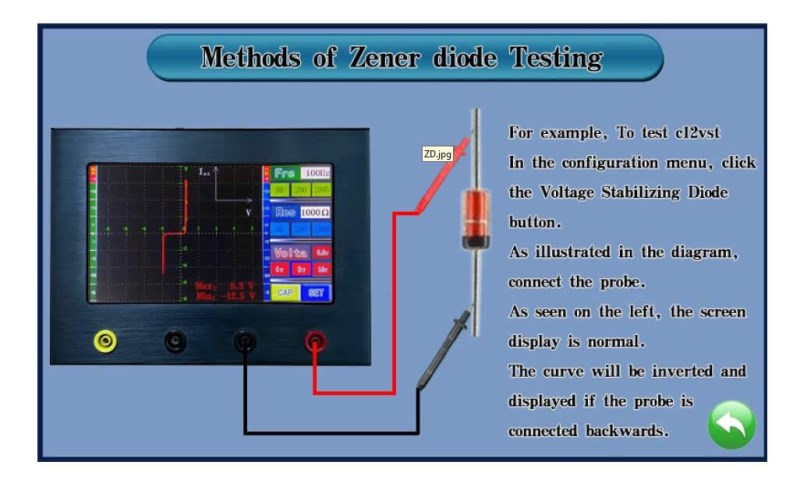

4. High voltage scanning mode, can directly read the value of Zener diode.

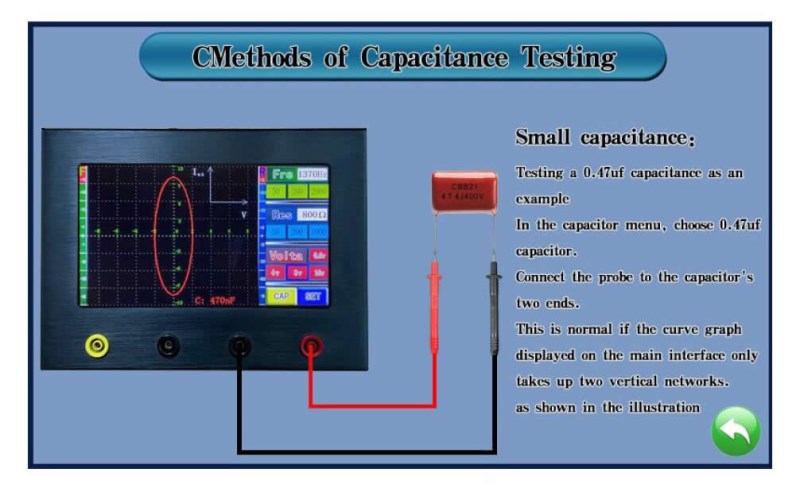

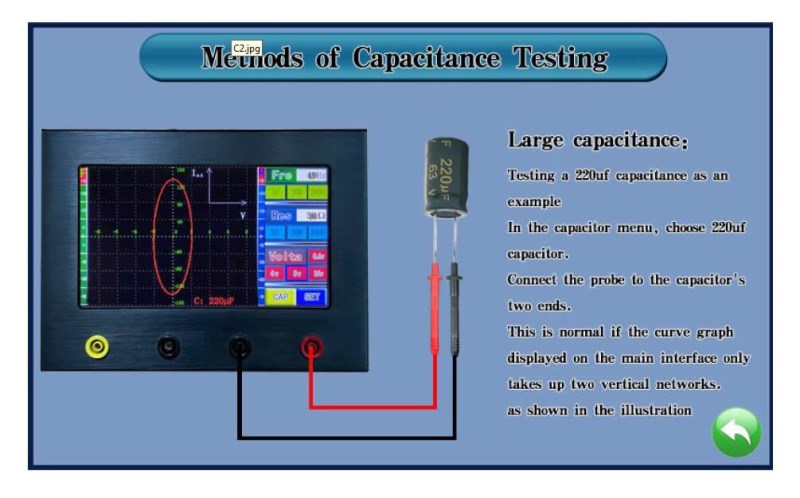

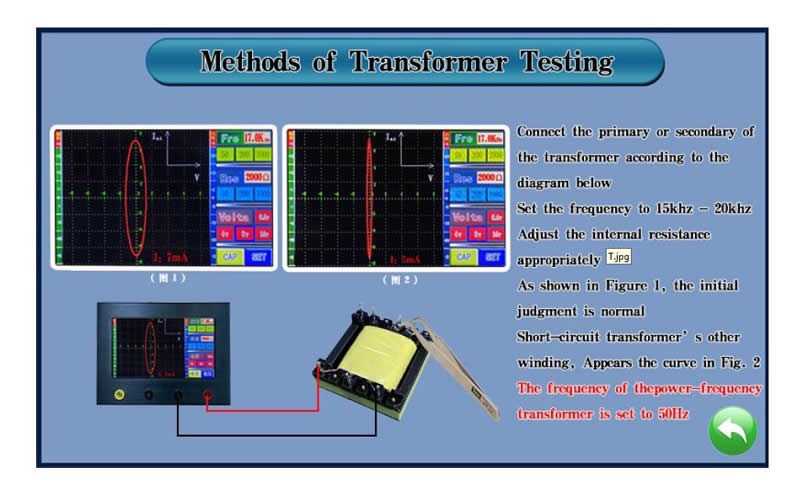

5. Have a very intuitive ability to judge difficult test components (such as transformers, capacitors, transistor soft faults, integrated circuits, etc.).

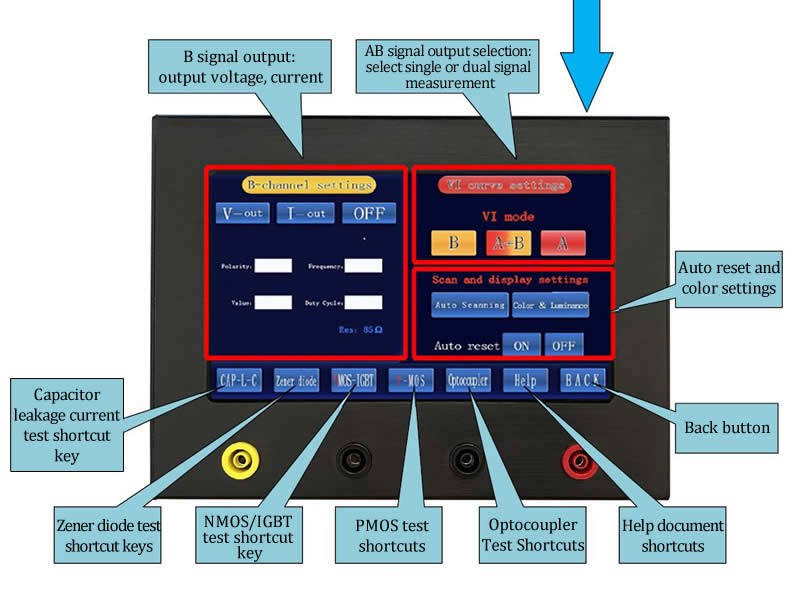

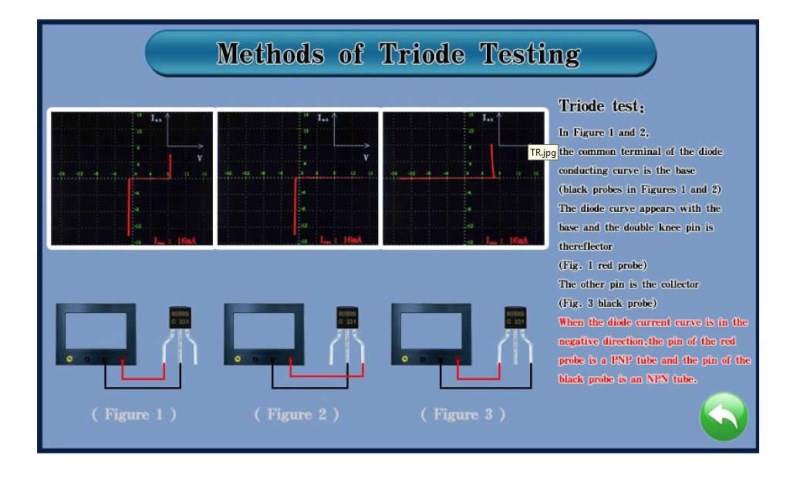

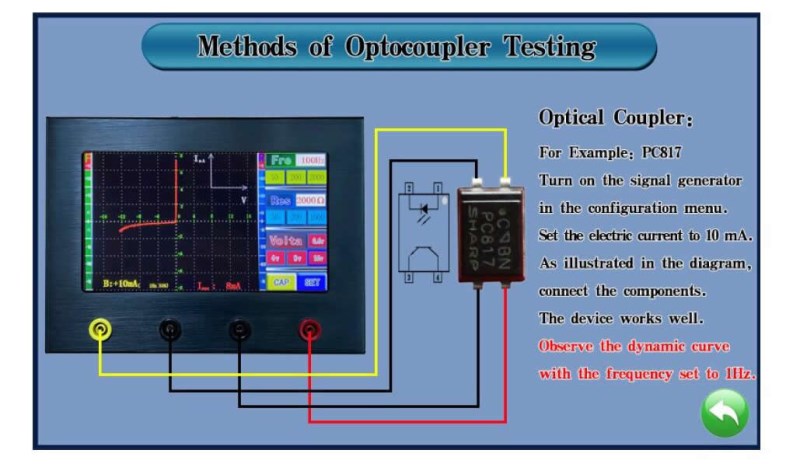

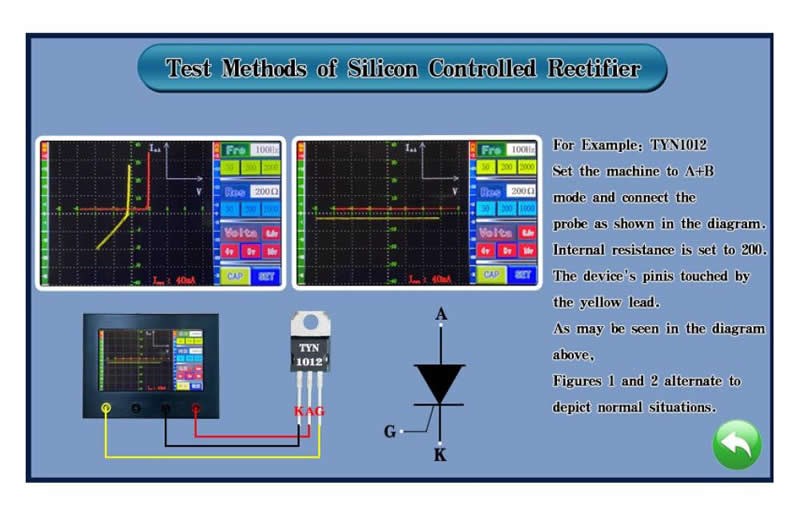

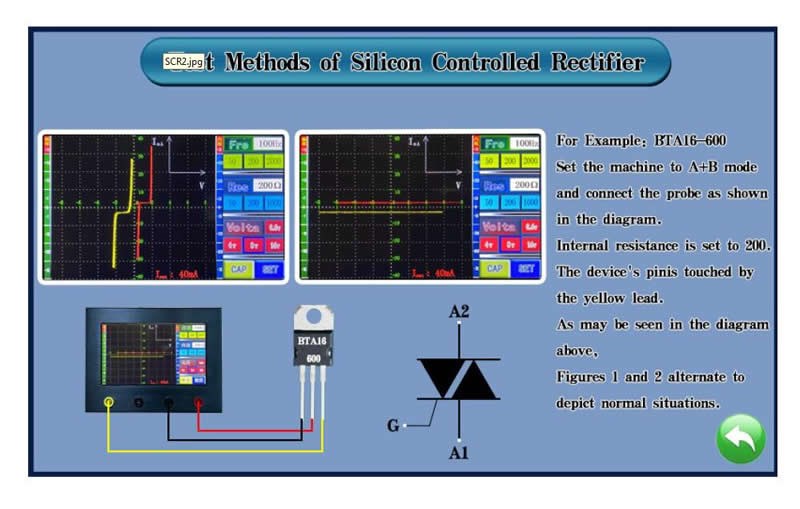

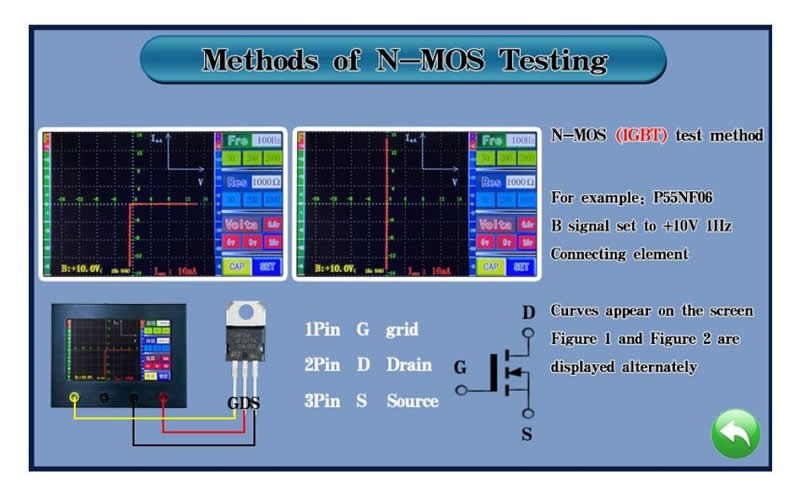

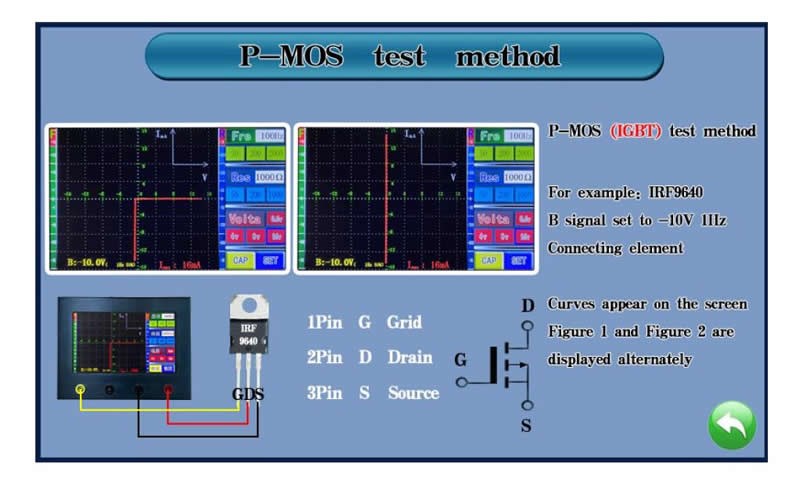

6. Built-in signal generator part, output controllable voltage and current signal, adjustable frequency and duty cycle, with VI curve can be used for various components (such as: triode, field effect transistor, thyristor, IGBT tube, various Optical coupling, driver chip, etc.) functional test.

7. The equipment is powered by 24V DC, and the adapter 110-220V can work, regardless of the region, the tester is compact and easy to carry, suitable for on-site maintenance.

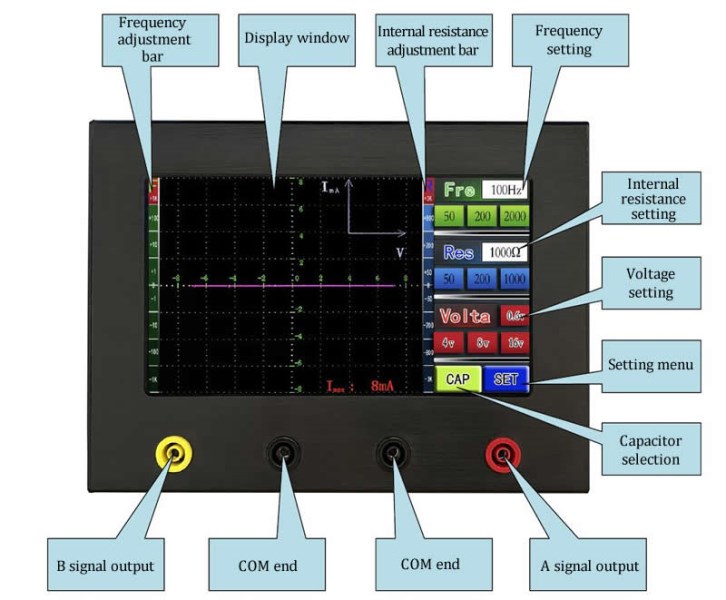

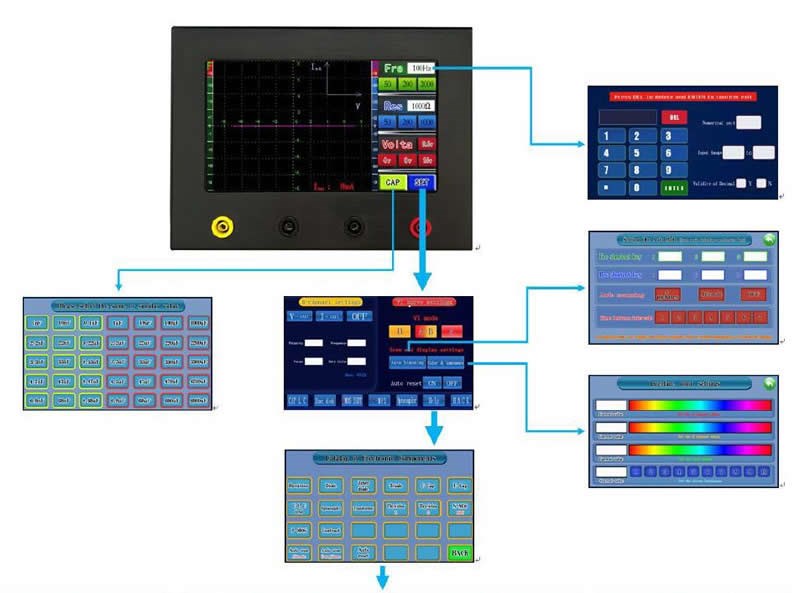

○1: Adjust up when two-way curve

○2: Adjust down when two-way curve

○3: Adjust to the left in the case of two-way curves

○4: Adjust to the right in the case of two-way curves

○5: Frequency shortcut bar setting, press the area on the right side of the corresponding number in the box to quickly add ? and subtract values

○6: Set the internal resistance shortcut bar, press the left area of the corresponding number in the box to quickly add and ? ? subtract values

○7: Press the middle cross area to restore the default parameter settings

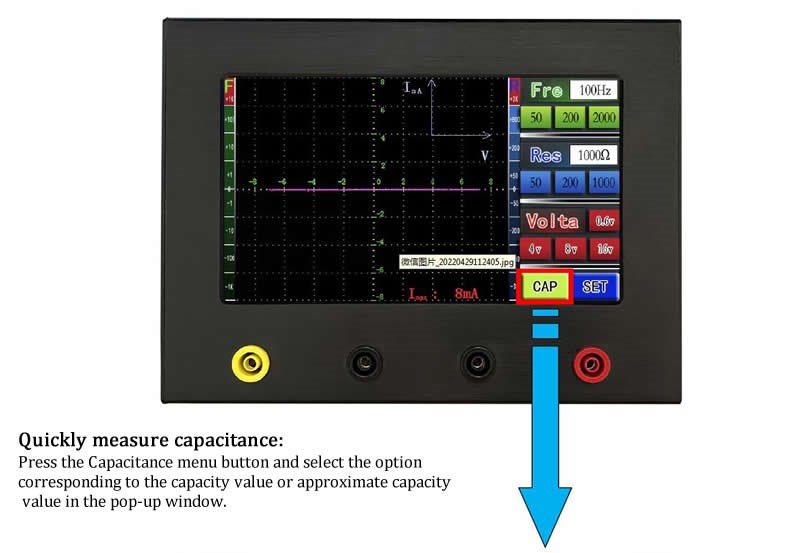

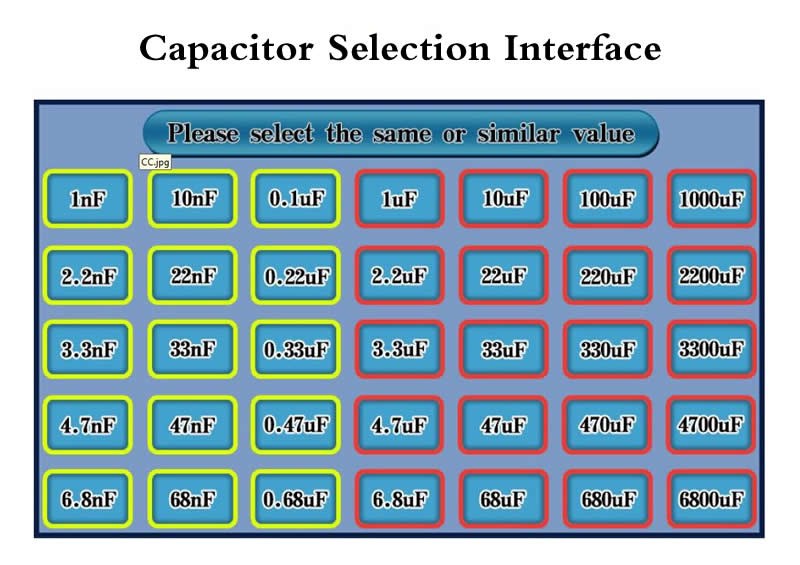

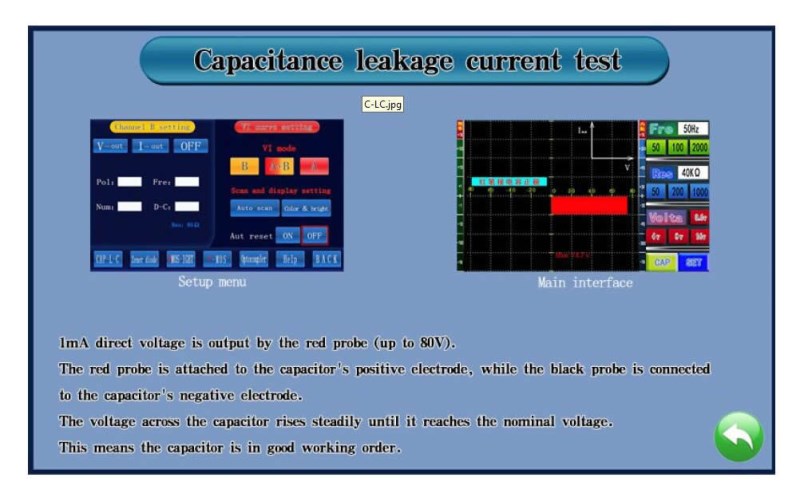

Capacitance Menu

Shipping List

Host*1pcs

Power supply*1pcs

Cable*1 Pair

(As picture below)