Type:Logic ICs

Condition:New

Supply Voltage:V

Dissipation Power:W

Operating Temperature:C

Application:0

Output type:Switch sensor

Sensor class:Liquid level sensor

Texture of material:mixture

First, product overview

Non contact type liquid level sensor (hereinafter referred to as the intelligent liquid level sensor) using advanced signal processing technology and high-speed signal processing chip, break through the influence of the wall thickness, the height of the liquid level in the sealed container real non contact detection. The liquid level sensor (probe) is installed in the upper and lower part of the outer wall of the tested container (high and low liquid level), and the non metal container does not need to open the hole, and the installation is simple and does not affect the production. The liquid level can be realized on the high pressure sealed container of toxic substances, acid and alkali and other liquids were detected. The liquid level sensor has no special requirements for the material of the liquid medium and the container, and can be widely used.

XKC-Y26-V products specifically for the development of non metal pipeline level detection.

Two, product characteristics

The n XKC-Y26-V sensor, suitable for non metal pipe without direct contact with the liquid, will not be affected by the corrosion of acid alkali and other corrosive liquids, no scale or other debris impact.

N intelligent liquid level adjustment and level memory function, liquid level display mode, can realize multi point series connection.

N detection accuracy and stability, can be detected boiling water level.

N pure electronic circuit structure, non mechanical working mode, stable performance and durability.

N high stability, high sensitivity, strong interference ability, not subject to external electromagnetic interference, for the power frequency interference and common mode interference to do special processing, in order to be compatible with all the5~24VThe power adapter

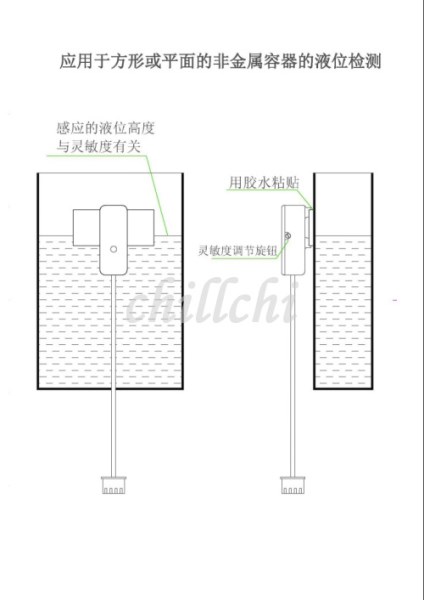

N strong compatibility, through a variety of non metal materials of the container pipe, such as plastic, glass, ceramics and other containers, the wall thickness of the induction tube20mmThe liquid level detection of a container or a pipeline which is suitable for various surfaces, arcs and cylindrical vessels.

N wide voltage range5~24V), suitable for connecting all kinds of circuit and product application.

Three, working principle

The intelligent non-contact liquid level sensor is induction capacitor use of water to detect whether liquid exists, no liquid in proximity sensor, the sensor because of distributed capacitance, so the inductor to exist certain static capacitance, when the liquid level rises close to the sensor, the parasitic capacitance will be coupled to the static liquid the capacitance, the capacitance sensor value becomes large, the change of the capacitance signal input to the controlICSignal conversion, the variation of the capacitance will change into a signal, and then by a certain algorithm to detect and judge the change degree, when the change exceeds a certain threshold that the liquid level reaches the induction point.

(please note that the customer to buy a good thank you!)

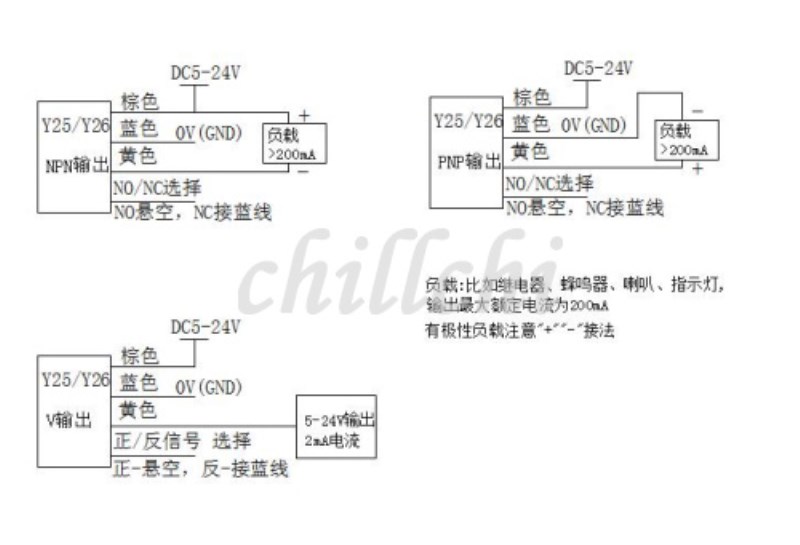

High and low level output interface - type:XKC-Y26-T12V(default)

NPNOutput interface model:XKC-Y26-NO (NPN)

PNP output interface - model:XKC-Y26-NO (PNP)

Four, product parameters

| entry name | parameter |

| Input voltageVin) | 5~24 V DC |

| Current consumption | 5mA |

| Output voltage (Gao Dianping) | Vin |

| Output voltage (low level) | 0V |

| Output current | 1~100mA |

| response time | 500mS |

| Working environment temperature | 0~85C |

| Inductive sensitivity | Pipe ODD (mm) | Maximum tube wall thicknessL (mm) |

| DMore than100 | 20.2 |

| 100>DMore than80 | 15.2 |

| 80>DMore than60 | 12.1.5 |

| 60>DMore than40 | 7.1.0 |

| 40>DMore than30 | 5.1.0 |

| 30>DMore than20 | 3.1.0 |

| 20>DMore than10 | 1.5.0.5 |

| Scope of application of pipe diameter | More than10mm |

| Liquid level error | .1.5mm |

| humidity | 5%~100% |

| Texture of material | ABS |

| Waterproof property | IP65 |

Five, Application conditions

(a) the measured liquid medium viscosity

Dynamic viscosity<10mPaSTime normal measurement.10mPaS<Dynamic viscosity<30mPaSMay affect the detection. Dynamic viscosity>30mPaSWhen a large amount of liquid is attached to the vessel wall, it can not be measured.

Note: with the increase of temperature viscosity decreased, most of the high viscosity of the liquid temperature effect is more obvious, so the viscosity of liquid in the measurement of attention to the effect of liquid temperature.

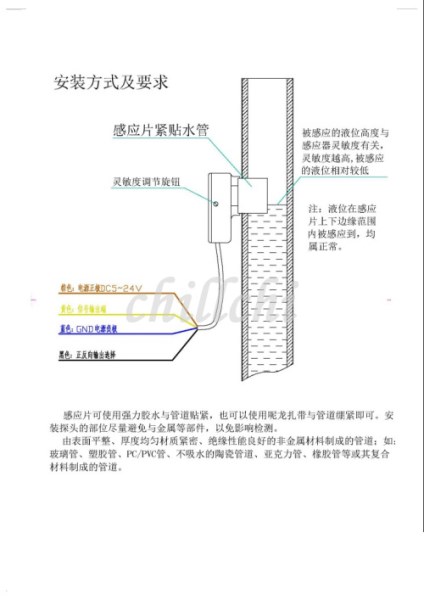

Six, Installation method and wiring instructions

Terminal type:HX2.54-4P

Terminal spacing:2.54mm

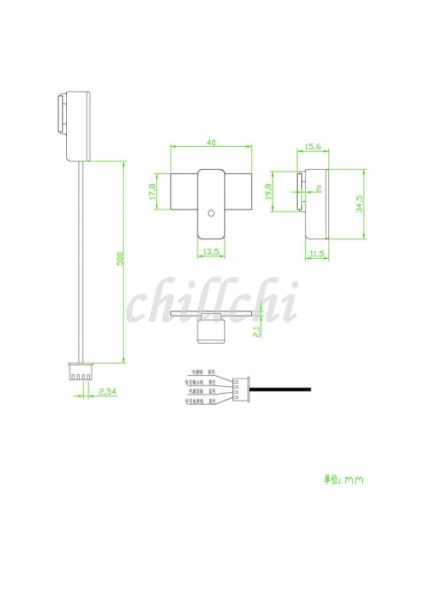

Seven, product size

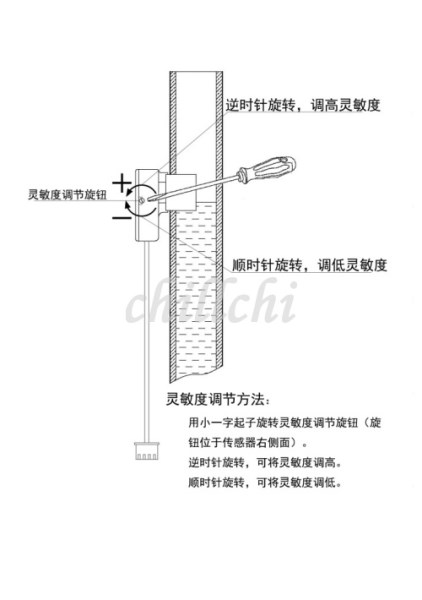

Eight, sensitivity adjustment

Nine, product maintenance

1,Form top

Pay attention to the cleanliness of the liquid level gauge, try to prevent corrosion and avoid violent collision of other objects, blow.

Outdoor installation should avoid direct sunlight level meter main body, away from the heat source and pay attention to ventilation, if the ambient temperature exceeds the rated temperature, should take appropriate measures to protect the cooling.

When the environment temperature is too low, the instrument can be used to protect the box or other protective device for anti freezing protection, and pay attention to keep the level of dry.

The sensor should be regularly maintained and checked. (inspection interval is determined by the use of the unit according to the specific circumstances).

Ten, troubleshooting

Form top

| Fault condition | Cause analysis | Solution measures |

| The liquid level sensor does not have any response after the electricity (water level reaches the induction point indicating light is not bright, the sensitivity adjustment does not have the reaction). | The power no good | Check and connect the power supply. |

| The positive and negative end of the power line is connected with the reverse | Correct wiring |

| Power module damage | Replace the circuit board where the power supply module is located |

| | Transfer the sensitivity to the appropriate gear |

| The indicator light is always on | Sensitivity stall is too high | Transfer the sensitivity to the appropriate gear |

| Initialization parameters are modified | Return the re initialization |

| The sensor has a foreign object or other metal parts close to the | To clean up the debris, and maintain a certain distance from the metal parts |