Condition:New

Type:Logic ICs

This heat transfer machine has been on the market . ?It has accumulated more than 5,000 sets.The circuit board of 10cm*15cm can be transferred in only 70 seconds, which is about 4 times faster than the previous transfer machine, and the effect is better, making your work more efficient!

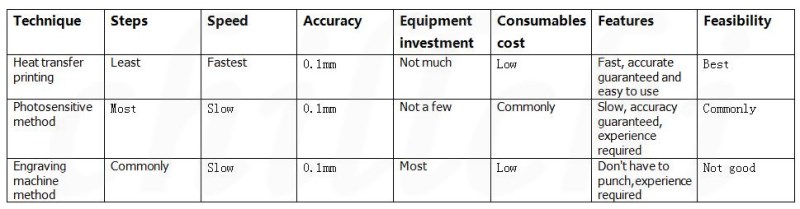

There are currently three popular methods for making circuit boards under amateur conditions: photosensitive, transfer and engraving.

It can be seen that for amateur circuit boards, thermal transfer is the best, of course, there must be an easy-to-use thermal transfer machine! Photosensitive second, the engraving machine, who knows who uses it!The 230A for science and education, are different from the general plastic machine in that the speed can be controlled, and the step-by-step transfer method is adopted, and the effect is quite good. In the past three years on the market, more than 5,000 units have been sold and sold to higher institutions nationwide. Schools, such as Tsinghua University, Wuhan University, Sichuan University, Xiamen University, etc., scientific research units such as the Institute of Magnetic Dynamics, the Institute of Oceanography, the Institute of Nanotechnology Development, etc.,It is a very mature machine. Nowadays, Science Education Electronics has launched two new machines, ZY-230B and ZY-320B, which have corrected the shortcomings of 230A and the shortcomings of functions! Make the machine more humane and easier to use!

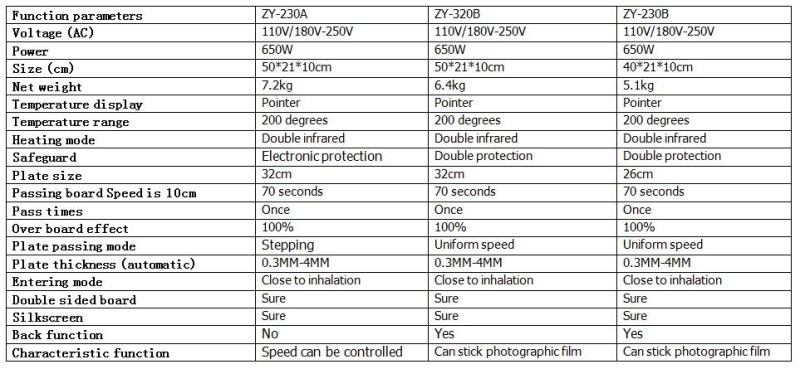

Comparison of three models:

After reading the form, add a note:

1. This machine retains the reverse function, so that the functions of the plastic machine can be completely retained. After taking photos at home, it can also be used as a photosensitive film sticking machine. The effect is very ideal, and it can achieve three functions in one machine.

2. When doing circuit board transfer, since the thickness of the commonly used circuit board is 0.6MM to 3.0MM, in order to make the machine more perfect, it is equipped with pressure feedback, and the circuit board in the range of 0.3MM to 4.0MM does not need any adjustment. Direct use, no need to consider the thickness of the circuit board, plug and play, very user-friendly!

3. It has an automatic suction function, as long as the circuit board is close to it, it can be automatically sucked in. It is very convenient and also a very user-friendly improvement.

4. The transfer machine is a high-temperature heating machine. Although there is electronic temperature protection, any machine will fail. The continuous increase in temperature may cause fire. Therefore, this machine adds a temperature protection on the original basis, using physical temperature protection. Once the temperature is out of control, the second protection will start to cut off the power supply and will not automatically reset. Even if the temperature drops to 0 degrees, it will not be powered on. It can only be reset manually, making the machine safer to use. This can be said to be revolutionary. The breakthrough greatly reduces the potential safety hazards and makes the use more secure.

5. Fast speed. This can be said to be the most efficient heat transfer machine on the market. It has the fastest speed. Of course, it will transfer 100% without any residue! The perfect transfer guaranteed under the premise of fast speed!Although the ZY-230A transfer machine is easy to use, but the transfer speed is not fast enough, personal use is good, not only a few minutes, it can be accepted, no matter what, it is 10 times faster than the photosensitive plate making method, if it is a school To use, many students will have to wait in line. This efficiency is too low. Taking a 10*15 cm long circuit board as an example, the transfer is completed in about 3 to 4 minutes. A class is even 50 students per person. One board is 50 pieces. It takes more than 200 minutes at the fastest and 45 minutes for a class. I am afraid that it will not be completed in one morning. If it is the new 320B, it only takes 70 seconds for a board. The difference between 320B and 230A is, andYou can enter the boards side by side without affecting each other. At the same time, you can enter 2 boards, which is 25 times. As long as about 30 minutes, one lesson is completed, which greatly improves efficiency and reduces workload! Reduce school equipment investment!If you want to mass produce circuit boards, time is a matter of seconds, and efficiency is money! So the improvement of 320B and 230B is of great significance!The speed is 4 times faster, and the efficiency is increased by 400%. Whether it is a school, a scientific research unit, or an individual small batch production, you can save several times the time. In an age where time is money, the economic benefits of saving time are very obvious. . Buying the right machine saves time, effort and value!

6. The transfer effect is 100% perfect transfer, and it is successful in one pass. A 100% transfer does not mean perfect transfer. The uniform speed transfer is used, and the toner will not be deformed or overflow! This is because uniform speed transfer canThe heat transfer paper is heated in a very comprehensive and balanced manner, and the transfer paper will not be stretched and stretched like the step transfer. This is an important reason for the easy deformation of the step transfer. The uniform speed transfer does not There will be this problem! Therefore, the uniform speed transfer is better than the step transfer, and the pattern is more beautiful! Friends who have a step-by-step transfer machine on hand can take a closer look. For example, 230A and fast transfer, step-by-step transfer transfer, lost steps, and backwards happen frequently, and uneven heating causes deformation of the toner. It is inevitable that the thin parallel lines of the transfer are very easy to see, but this kind of deformation is acceptable, and the improvement is for better and more efficient!The 230B and 320B use uniform speed transfer to avoid several problems of step transfer, making the transfer effect more perfect, and more faithfully restore the content on the transfer paper, which is 100% transfer!

7. Double infrared heating, when making double panels, two sides can be transferred at the same time! higher efficiency. The deformation is small, the double-sided alignment is more accurate, and the temperature displayed by the meter is intuitive and obvious!

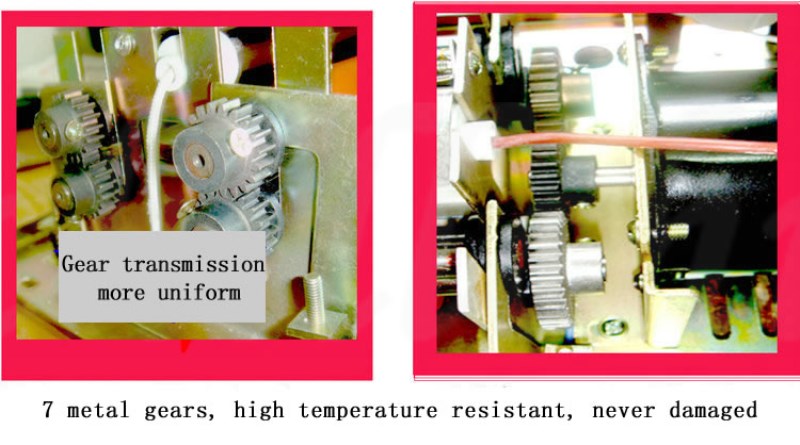

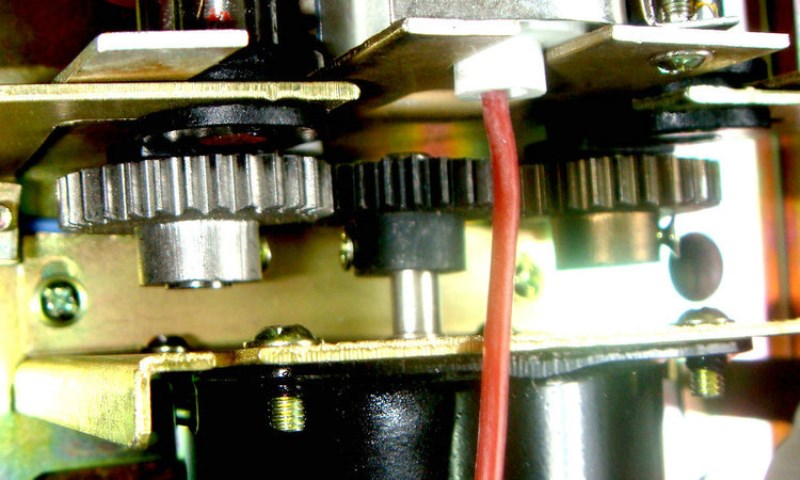

8. What is the quality of the machine that everyone is concerned about? It can be said that the material used in this machine is the most high-end and the cheapest: it uses 7 all-metal gears, the advantage is that it is not afraid of high temperatures and durable! The conventional transfer machine has 3 gears. The rotation between the upper roller and the lower roller is completely frictional, which makes it easier to shift. Using 7 gears, the upper roller and the lower roller are driven by gears without displacement. The temperature control board is redesigned on the original foundation, and higher temperature resistant accessories are used. If it is a conventional machine accessory, it will burn under this temperature condition, so ordinary over-molding machines (or transfer machines) cannot do this Change it to a uniform speed (please don't imitate the high temperature yourself), this machine has dual temperature protection, it is safe to use! specializedCustomized motor, Did temperature compensation, and adoptedCustom glue stick, Make the temperature resistance higher and more durable!

Here is an example, make an introduction, learn well,Understand thoroughly,The key depends on practice.....

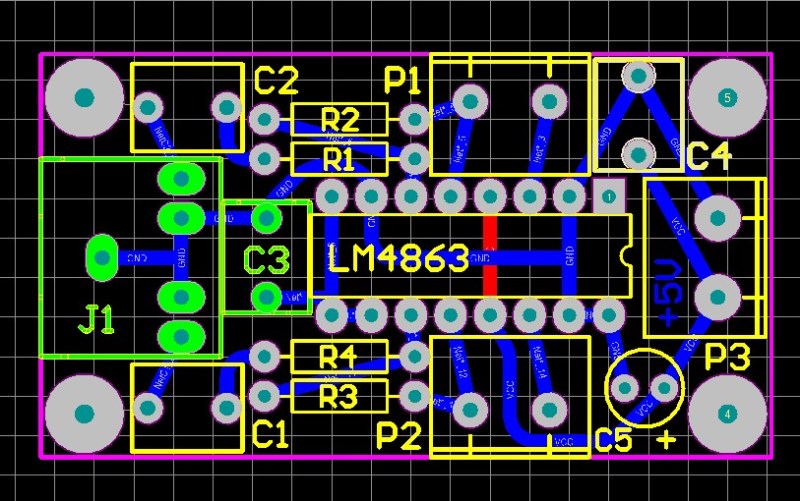

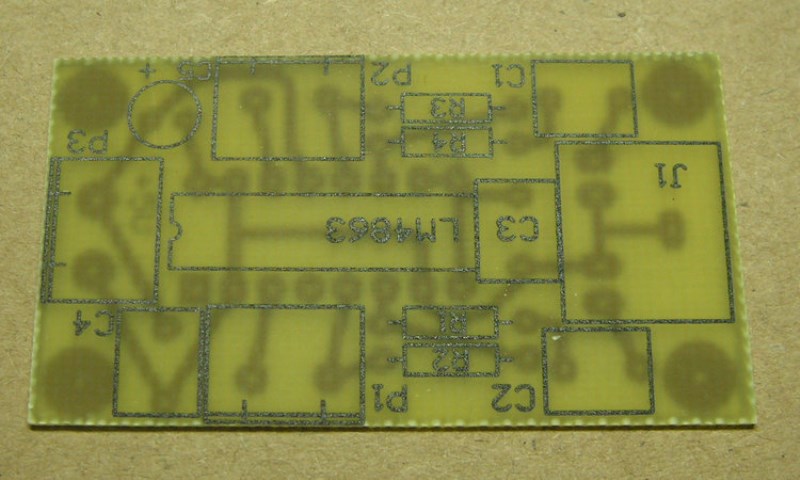

First draw the circuit diagram, any software is fine, it is recommended to usePROTEL, Of course others are fine, as long as it can be printed, as shown below, draw oneLM4863Power amplifier circuit diagram!

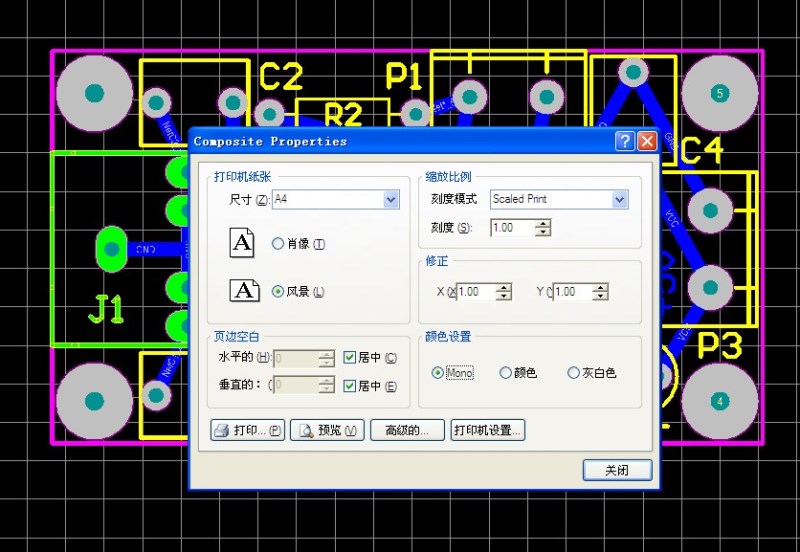

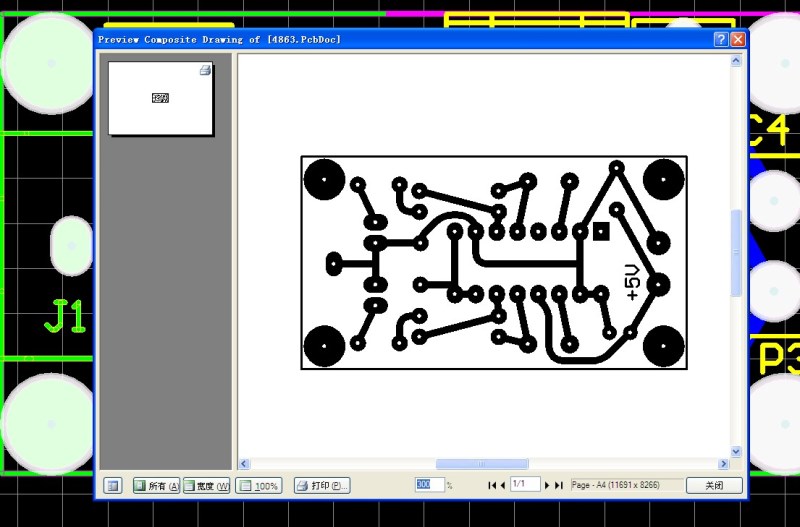

Set up printing

Precautions: 1,press1:1Print, set the scale mode toScaled Print,Scale is set to1.00

2,Color is set toMono(monochrome)

3, The printed paper is generallyA4! Pay attention to these three points!

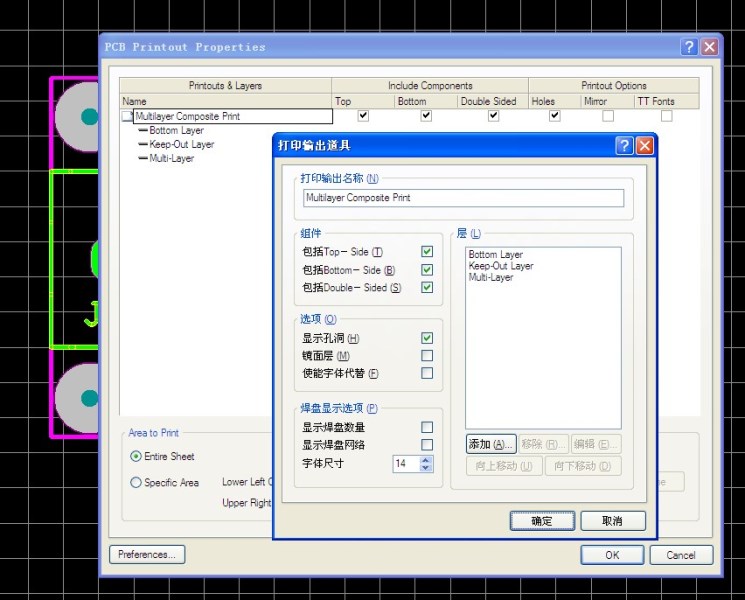

Print content settings, select the layer you want to print, the single panel is for example:

Print the bottom layer (circuit part) without mirroring!

Printing prohibited wiring layer (frame)

Print solder holes (and show holes)

Hit the heat transfer paper: Use scissors to cut out the circuit diagram part.

Prepare the circuit board, use a cutting board knife to cut the size to fit the size, at least larger than the circuit diagram!

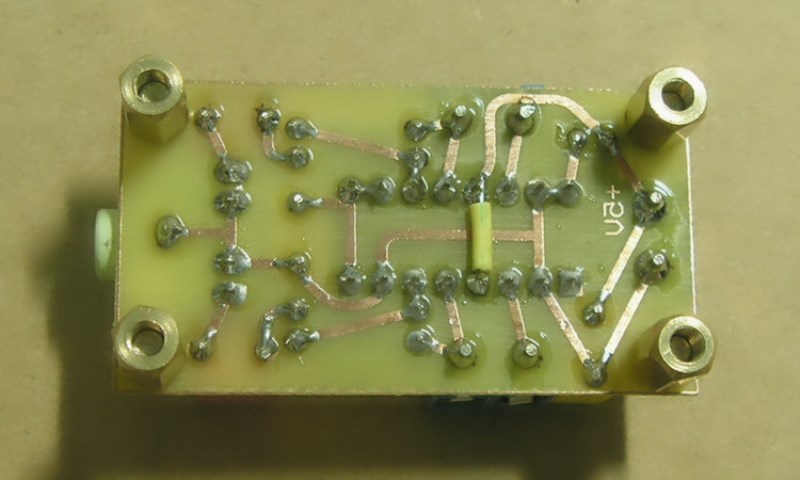

Ready, science and education ZY-320B heat transfer machine, high temperature tape for fixing paper,Put the printed transfer paper on top of the cut copper plate! With the printing layer facing down, fix it with tape!

The transfer machine is turned on and heated until the green light comes on. In order to see the whole process more intuitively, remove the transfer cover!

Put the printed circuit board with transfer paper into the heat transfer machine to transfer!

LatestZY-320BThe transfer speed is very fast,10Cm length of the circuit board as long as40About seconds, this transfer is less than20Seconds, and 100% transfer is successful in one pass, which is easier to use than any transfer machine on the market!

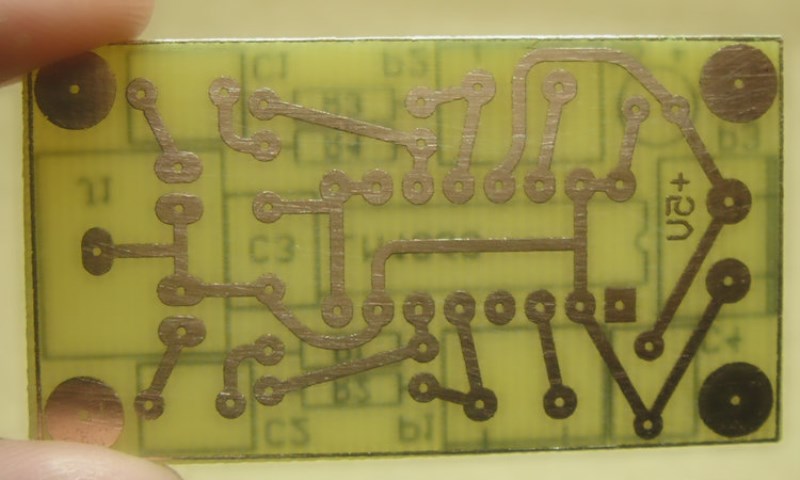

Without any residual toner, the transfer effect is perfect! Super fast!

After the transfer is completed, it can be corroded. Corrosion uses a corrosion box and a heating rod!

put into a2Pack an environmentally friendly corrosive agent and add appropriate water, and the heating rod and the motor are powered on!

The board looks corroded in the corrosion box!

Because of the corrosion box, the corrosion rate is very fast, less than3It's done in minutes, very cool!

After the corrosion, the silk screen layer can be made!

Precautions for silk screen layer:

The silk screen layer should be mirrored!

When transferring the silk screen layer, the circuit board must be corroded first, do not punch holes. Under the light, the circuit board is transparent, so the silk screen and the circuit are very easy to align! If you want silk screen layers of various colors, please use a color laser printer!

The transfer wire is the same method as the transfer circuit, so I won't elaborate on it here!

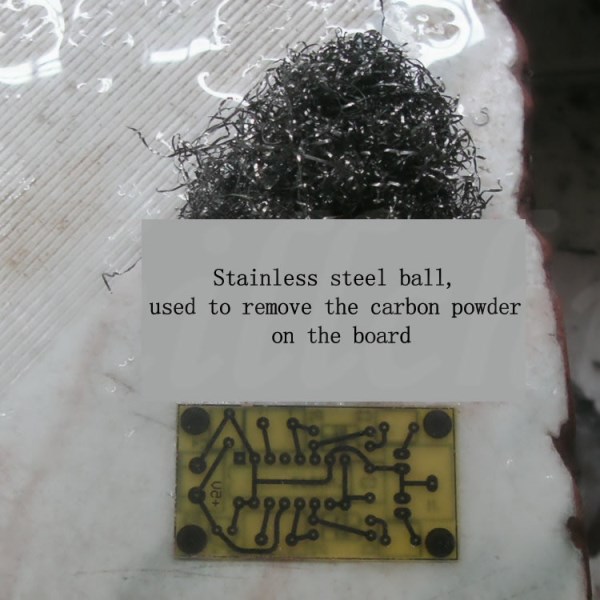

To remove the toner, it is recommended to use a wire ball for dishwashing, which is convenient, fast, and inexpensive, and is much better than sandpaper! Scrubbing in water is convenient and fast!

The circuit board is transparent under the light!

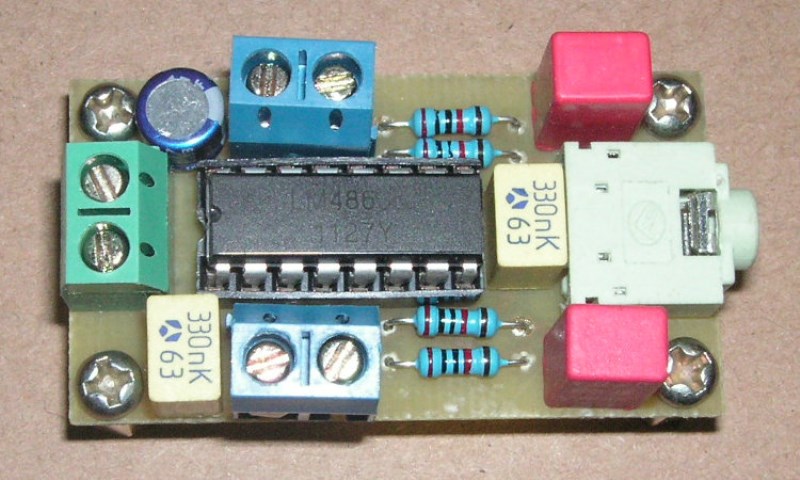

Install components:

end:

This is the end of a very interesting power amplifier manufacturing process. With the heat transfer machine, a lot of electronic experiments can be completed!

As the saying goes, one machine in hand, no need to worry about electronic production! The transfer machine is very useful, and other things are also essential!

Summarize the experience:

When printing, the pad of the circuit should be set larger. It is recommended that the pad be2mmLeft and right, the holes are0.5mm,When drilling holes, choose a suitable drill bit size, this is easy to align! No deviation!

Print the bottom circuit diagram directly, the top circuit diagram should be mirrored printing, and the silk screen layer should also be mirrored printing!

3,The temperature of the transfer machine is open to200Degree, the board should be larger than the thermal transfer paper to facilitate the tape fixation!

When corroding, use environmentally friendly corrosive and heat the temperature to60The corrosion rate is very fast!

The double-sided board is just repeated twice for the single-sided board! It is recommended that the two sides be divided into two boards, one board on the top layer and one board on the top layer, and then put them together to form a double-sided board. Through this method, a multilayer circuit board can be made!

When using double-sided panels to make double-sided panels, do it one side by side. After one side is transferred, the other side is sealed with tape, and after corrosion, after the corrosion, a few positioning holes are punched and aligned with the positioning holes. Fix the tape transfer, and then transfer the other side, and then corrode! The double panel is complete!