Brand Name:icchipcn.com

Condition:New

Type:Logic ICs

Product Parameter:

Product name: Three-phase torque motor speed control module

Model (demonstration): TSR-10WA-SL, TSR-60WA-HL (SL is aluminum bottom, HL is copper bottom)

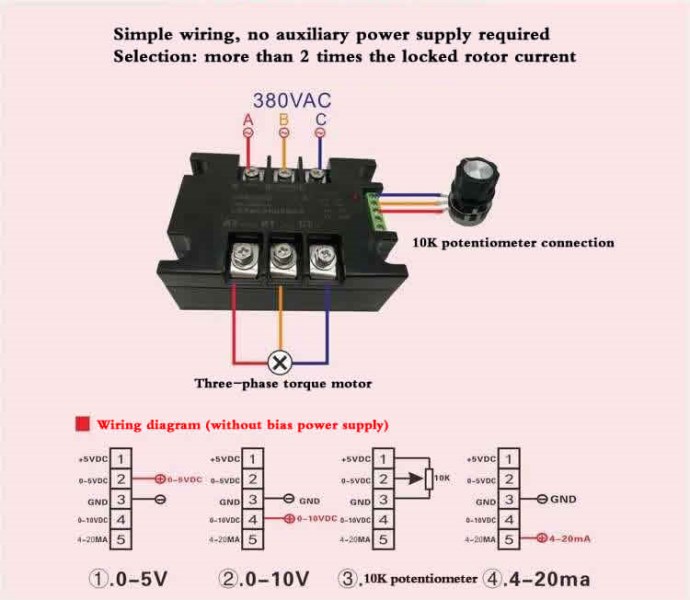

Compatible signal: 4-20MA, 0-5V, 0-10V, 10K potentiometer

Rated current: 10A20A, 40A, 60A, 80A, 100A, 120A, 150A, 200A

Load voltage: 380VAC

Medium withstand voltage: 2000VAC

Off-state leakage current: ≤5MA

Ambient temperature: -30C~+70℃

Control current: ≥10MA

On-state voltage drop: ≤1.5V

Dimensions: 105L×75W×45H

Net weight: 500 grams

Product Description:

? ? ? The torque motor speed control module is a new type of modular torque motor speed control controller independently developed by our company. It has the characteristics of input and output photoelectric isolation, phase-shift voltage regulation circuit and main circuit integration, small size, light weight, long life, large control power, stepless adjustment, and high insulation voltage. It is convenient to use the voltage change of the input terminal to realize the automatic control of the load power of the output terminal, and the potentiometer can be used to adjust the output power manually. At the same time, the input impedance is high, and the internal synchronization can be directly connected to the computer, digital program-controlled circuit and instrument interface with 1-5V, 0-10V voltage or 4-20mA current output through the digital-to-analog converter, which is very convenient to realize the output Stepless regulation of terminal load voltage power. TR” AC output is mostly used for inductive loads, and can be widely used in industrial electric furnaces, electric ovens, lighting, primary voltage regulation on the primary side of transformers and other equipment for temperature regulation, dimming, voltage regulation and other controls. Fans, pumps, three-phase torque motors for speed regulation and other occasions.

Product Features:

? ? The three-phase torque motor speed control module integrates three-phase electrical phase detection, phase-shifting circuit, trigger circuit and three sets of anti-parallel one-way thyristors, without external synchronous transformer, 1-5vdc, 0-10vdc, 4- 20mA signal automatic control or external potentiometer (10K) manual control, to achieve stepless adjustment of the three-phase load voltage from 0V to the full voltage of the grid by changing the conduction angle of the thyristor.

long life

no noise

no spark

completely isolated

Fast switching speed

Scope of application

1. Torque motor speed regulation

2.50-60HZ compatible

3. Compatible with a variety of analog signals

4. Improved materials, no attenuation components, and long service life

5. Input signal: 4-20MA, 0-5V, 0-10V, 10K potentiometer

Precautions for selection of solid state relay products:

1. When choosing a product, different margins should be left on the current level according to the nature of the load. (For resistive load, it can be selected by 2-3 times the load current. When inductive or capacitive load, it can be selected by 3-5 times the load current, and the motor can be selected by more than 5 times.)

2. According to the relationship between the load current and the ambient temperature, when the ambient temperature is high or the heat dissipation conditions are not good. The current capacity should be increased. In order to prevent the short circuit of the load during use, it is required to connect the corresponding quick disconnect switch or quick fuse in the load circuit in series.

3. When the load is inductive, a varistor should be connected in parallel at the output end to prevent damage to the thyristor during overvoltage. Varistor (M0V) selection: 430-470V for 240V, 680-750V for 440V.

4. During installation, it is required that the contact surface between the radiator and the product must be flat and clean, and a layer of thermal conductive silicone grease should be evenly coated on the surface. Finally, the screws covered with flat washers and spring washers should be tightened symmetrically.

5. When the solid-state relay stops working for the first time, the fixing screws should be tightened while the residual temperature is still there, so that the solid-state relay base plate and the surface of the radiator can be in close contact to achieve the ideal heat dissipation effect.

6. The nominal current of different types of solid state relays is the nominal current when the ambient temperature is 40°C, so the heat dissipation should be sufficient! !

7. Be careful not to use a multimeter on the load side to judge the quality of the product!